Robotic Grinding and Polishing Services for Modern Industry

- Home

- Why Your Robotic Grinding and Polishing Machine Need a Custom Gripper

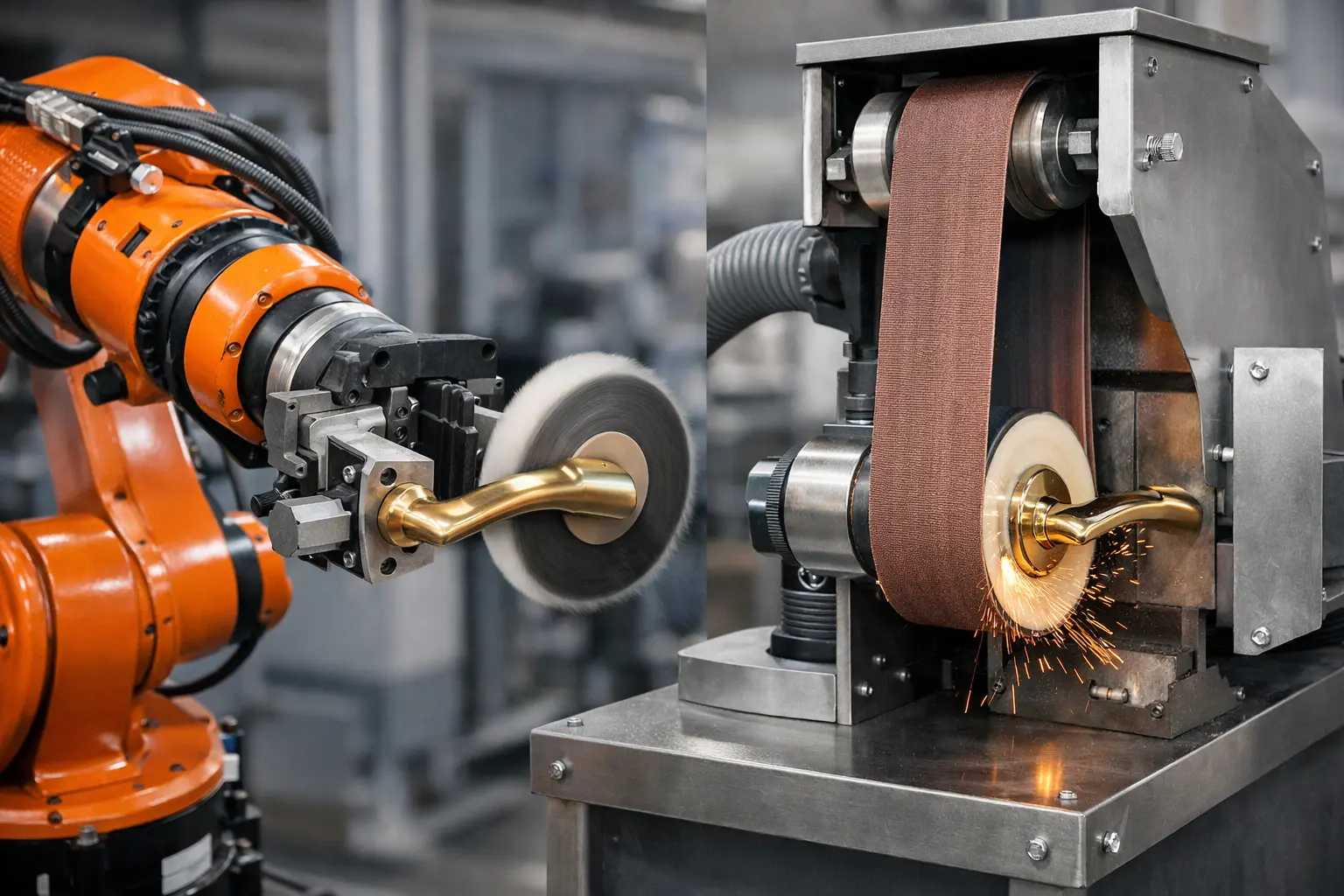

Introduction: Precision at Scale in Modern Surface Finishing

In today’s manufacturing landscape, surface finishing is no longer a secondary operation. It is a defining factor in product quality, brand perception, and operational efficiency. From automotive body panels to aerospace components, from consumer appliances to precision molds, polishing determines not only how a product looks but also how it performs and lasts.

As industries move toward automation, the robot polishing machine has emerged as a cornerstone technology. Companies adopt robotic systems to achieve consistency, reduce labor dependency, improve safety, and scale production without sacrificing quality. Yet many manufacturers discover an uncomfortable truth after deploying robots: buying a robot is not the same as achieving robotic excellence.

The difference between an average setup and a world-class solution often comes down to one overlooked component — the grip.

This article explores why a custom gripper design is essential for scaling excellence in robotic polishing. We will examine the challenges of polishing automation, the limitations of generic tooling, and how a purpose-built grip transforms a car polishing robot, robot arm polishing system, or any robotic grinding and polishing cell into a high-performance, future-ready solution.

The Evolution of Robotic Polishing

From Manual Craftsmanship to Automated Precision

For decades, polishing was considered an art. Skilled operators relied on experience, touch, and intuition to produce flawless finishes. While craftsmanship delivered excellent results, it also came with limitations:

- Inconsistent quality across shifts and operators

- High labor costs

- Worker fatigue and injury

- Limited scalability

The introduction of polishing robots changed this equation. Robots brought repeatability, endurance, and process control into surface finishing operations. Early systems, however, were rigid and difficult to adapt.

Modern robotics polishing solutions combine advanced robot arms, force control, vision systems, and intelligent tooling. Yet even with these advancements, one mechanical interface remains central: the gripper.

Why the Gripper Matters More Than You Think

In robotic polishing, the gripper is not just a holder. It is the physical connection between:

- The robot arm

- The polishing tool

- The workpiece

Any instability, misalignment, or force imbalance at this interface directly affects surface quality, tool life, and cycle time. As production scales, these small inefficiencies multiply into significant losses.

Understanding the Role of the Gripper in Robot Polishing Machines

A robotic gripper design defines how effectively a robot interacts with its task. In polishing applications, the gripper must manage:

- Constant contact forces

- Variable surface geometries

- Tool vibrations

- Heat generation

- Dust and slurry exposure

Unlike pick-and-place operations, polishing is a continuous, force-driven process. The gripper must behave less like a clamp and more like an extension of the robot’s wrist.

Common Tasks Managed by a Polishing Gripper

A well-designed gripper in a robot polishing machine supports:

- Tool alignment and orientation

- Force transmission and compliance

- Quick tool changes

- Vibration damping

- Safety and collision tolerance

Without customization, these functions are often compromised.

The Hidden Limitations of Standard Grippers

One Size Does Not Fit All

Off-the-shelf grippers are designed for general-purpose handling. They prioritize flexibility across applications rather than optimization for one.

In robotic grinding and polishing, this approach creates challenges:

- Excessive rigidity causes chatter marks

- Insufficient compliance leads to uneven finishes

- Poor weight distribution strains the robot arm

- Limited sealing reduces durability in harsh environments

The Cost of Compromise

Manufacturers often attempt to adapt standard grippers with makeshift solutions. While this may work initially, long-term consequences include:

- Increased scrap and rework

- Inconsistent surface quality

- Higher maintenance costs

- Reduced robot lifespan

When scaling production, these issues become bottlenecks.

Scaling Excellence: What Changes When Production Grows

Many companies first deploy a robot polishing machine in a pilot setup. At low volumes, imperfections are manageable. As demand increases, expectations change:

- Higher throughput

- Tighter quality tolerances

- Minimal downtime

- Predictable performance

A gripper that was “good enough” at low volume often fails under continuous operation.

The Multiplier Effect of Small Inefficiencies

In a high-volume car polishing robot cell:

- A 1-second delay per cycle can cost hours per shift

- Minor surface defects can impact entire batches

- Tool wear accelerates exponentially

Custom grip design eliminates these inefficiencies at the source.

Why Custom Gripper Design Is a Strategic Advantage

Designed for Your Exact Application

A custom robotic gripper design is engineered around:

- Specific workpiece geometry

- Polishing tool characteristics

- Required surface finish

- Robot payload and reach

This alignment ensures that every component works in harmony.

Improved Surface Quality

Custom grips enable:

- Consistent contact pressure

- Stable tool orientation

- Reduced vibration

The result is a superior, repeatable finish across all parts.

Higher Throughput and Efficiency

Optimized grips reduce:

- Tool change time

- Setup adjustments

- Error recovery

This directly increases productivity in robot arm polishing operations.

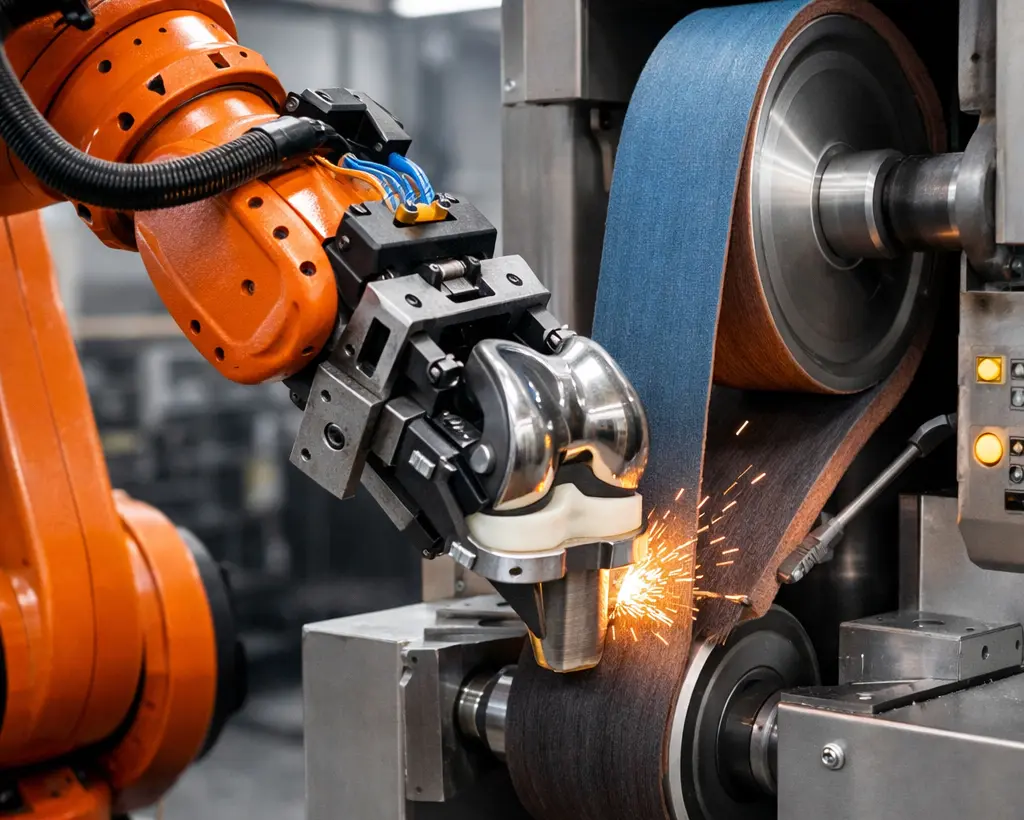

Custom Grippers in Car Polishing Robots

The Automotive Finish Challenge

Automotive surfaces are among the most demanding polishing applications. Curved panels, varying materials, and high aesthetic standards leave no margin for error.

A car polishing robot must adapt continuously while maintaining uniform pressure and motion.

How Custom Grips Make the Difference

Custom grippers for automotive polishing incorporate:

- Multi-axis compliance

- Lightweight materials to reduce inertia

- Integrated force sensors

- Quick-change tool interfaces

These features allow the robot to follow complex contours without sacrificing finish quality.

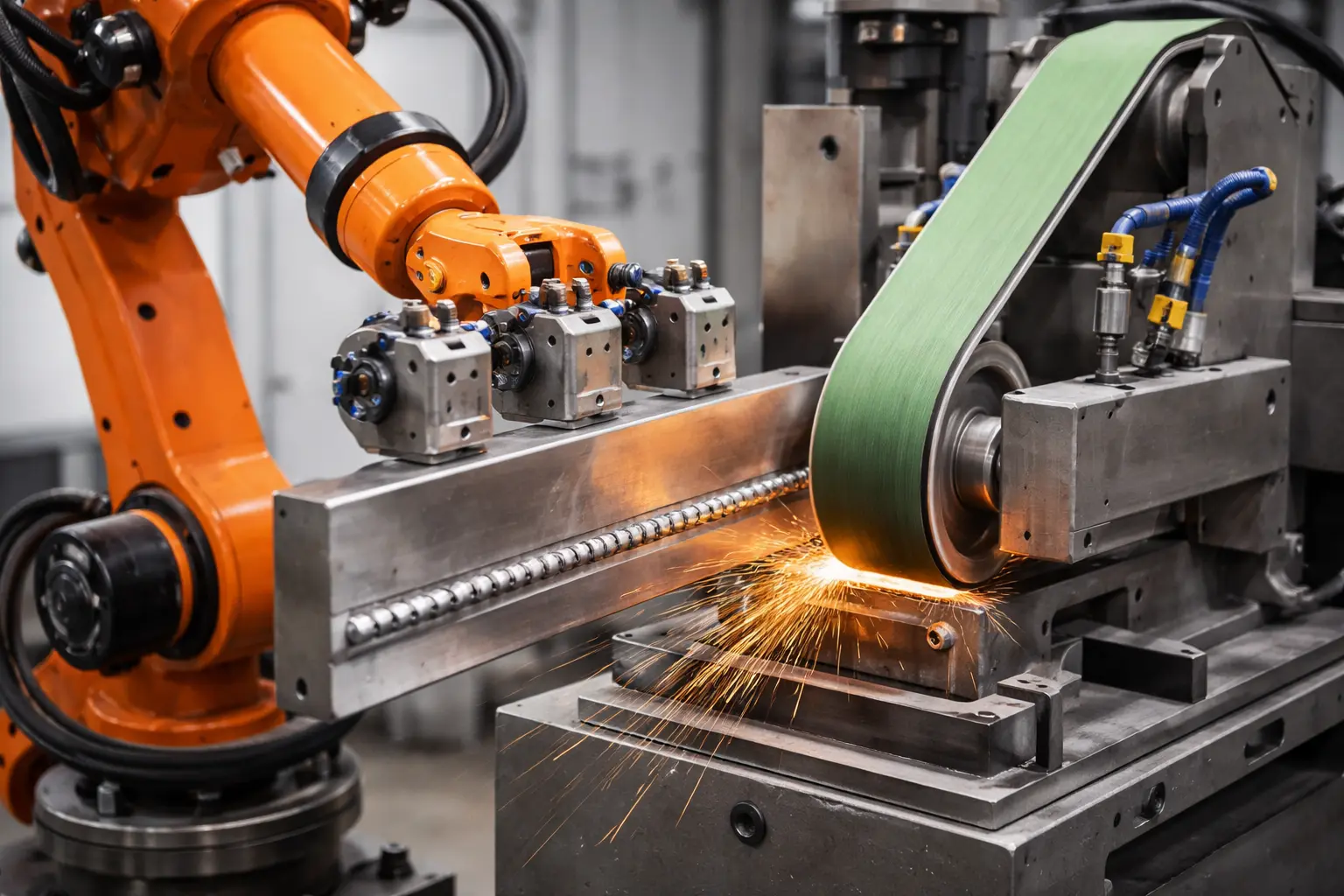

Robotic Grinding and Polishing: Managing Force and Stability

The Force-Control Challenge

Grinding and polishing are force-driven processes. Unlike position-based tasks, success depends on maintaining consistent contact pressure.

A poorly designed gripper disrupts force feedback loops, causing:

- Over-polishing

- Surface burns

- Inconsistent roughness

Custom Grip Solutions

Custom grips integrate seamlessly with force control systems, enabling:

- Precise force transmission

- Shock absorption

- Real-time adjustment

This transforms robotic grinding and polishing into a predictable, scalable process.

Robotics Polishing in Harsh Industrial Environments

Environmental Realities

Polishing environments expose equipment to:

- Abrasive dust

- Liquids and slurry

- Heat and vibration

Standard grippers degrade quickly under these conditions.

Built for Durability

Custom grippers are designed with:

- Sealed housings

- Corrosion-resistant materials

- Reinforced joints

This ensures long-term reliability in demanding robotics polishing cells.

Robot Arm Polishing and Payload Optimization

Balancing Reach, Weight, and Precision

Every additional gram at the end of a robot arm reduces:

- Speed

- Accuracy

- Component life

Generic grippers often add unnecessary mass.

Lightweight Custom Design

A custom grip is optimized for strength-to-weight ratio, enabling:

- Faster motion

- Lower energy consumption

- Reduced wear on the robot arm

This is especially critical in extended robot arm polishing applications.

Integration with Smart Manufacturing Systems

Beyond Mechanical Design

Modern polishing cells are part of connected factories. Custom grippers can integrate:

- Sensors

- Tool identification systems

- Predictive maintenance data

This transforms the gripper into a data-generating asset.

Supporting Industry 4.0 Goals

With smart grippers, manufacturers gain:

- Process transparency

- Quality traceability

- Continuous improvement insights

Safety, Compliance, and Risk Reduction

Protecting Equipment and People

Polishing involves high-speed motion and rotating tools. Custom grips can include:

- Torque limits

- Collision detection

- Emergency release mechanisms

This reduces risk in automated cells.

Consistent Compliance

Built-in compliance ensures safe interaction with workpieces, fixtures, and nearby equipment.

Economic Impact: ROI of Custom Gripper Design

Upfront Cost vs Long-Term Value

While custom grippers require initial investment, the return comes from:

- Reduced scrap

- Lower maintenance

- Increased uptime

- Extended tool life

Scaling Without Reengineering

A well-designed custom grip supports future expansion, avoiding costly redesigns.

Case Example: Scaling a Robot Polishing Machine

A manufacturer introduced a robotic polishing cell using standard tooling. Initial results were acceptable at low volume. As production increased:

- Surface defects rose

- Tool wear doubled

- Cycle times increased

After switching to a custom robotic gripper design, the company achieved:

- 30% cycle time reduction

- Consistent surface finish

- Lower maintenance costs

The gripper became the enabler of scale.

Best Practices for Designing a Custom Polishing Gripper

Start with the Process

Understand:

- Surface requirements

- Material behavior

- Tool interaction

Collaborate Across Disciplines

Involve:

- Automation engineers

- Process specialists

- Maintenance teams

Design for Change

Anticipate future:

- Product variations

- Tool upgrades

- Volume increases

The Future of Polishing Robots and Custom Tooling

Smarter, More Adaptive Systems

Future polishing robots will rely even more on intelligent end-of-arm tooling. Custom grips will evolve to include:

- AI-driven force adjustment

- Self-calibration

- Modular architectures

Competitive Differentiation Through Design

As robots become more accessible, competitive advantage will shift to how systems are designed and integrated. Custom grips will be a defining factor.

Conclusion: Excellence Is in the Details

A robot alone does not guarantee quality. True excellence in surface finishing comes from aligning every component with the process goal. The gripper, often underestimated, plays a decisive role in determining performance, scalability, and reliability.

Whether you are deploying a robot polishing machine, optimizing a car polishing robot, or expanding robotic grinding and polishing operations, investing in a custom grip is not a luxury. It is a strategic decision.

By embracing tailored robotic gripper design, manufacturers unlock the full potential of robotics polishing and robot arm polishing, transforming automation from a cost-saving tool into a competitive advantage.

Scaling excellence begins at the point of contact. Make it count.

Recent Posts

- Ultimate Guide to Engine Oil Additives for Emergency Engine Protection & Longer Engine Life

- Clean Engines, Strong Performance: Why Drivers Trust Molykul engine oil additive

- How a Smart Engine Oil Additive Can Reduce Vehicle Emissions and Protect Urban Air Quality

- How MoS2 Grease in Stone Mining Catalyzes Superior Machine Power in India

- Cutting Downtime and Maintenance Costs in Factory Machines

Products

-

MolyKul MoS2 Gear Oil additive for cars and bike| Anti-friction MoS2 Solution - 100ml

₹507.40Original price was: ₹507.40.₹338.66Current price is: ₹338.66. Including 18% GST -

MolyKul Aero-Spec 500 (MKG AS500 NG2) – MoS2 Anti-Seize Aerospace grease – 500 Deg C ₹1,770.00 – ₹8,254.00Price range: ₹1,770.00 through ₹8,254.00 Including 18% GST

-

MolyKul MoS2 Grease for industrial application| Lithium + Anti-Seize MoS2 - 650 Deg C

₹1,305.00Original price was: ₹1,305.00.₹991.00Current price is: ₹991.00. Including 18% GST -

MolyKul MoS2 engine oil additive for cars and bikes| Anti-friction MoS2 Solution - 100ml ₹166.00 – ₹450.00Price range: ₹166.00 through ₹450.00 Including 18% GST

-

MolyKul MoS2 Grease for industrial application| Lithium + Anti-Seize MoS2 - 320 Deg C ₹580.00 – ₹5,600.00Price range: ₹580.00 through ₹5,600.00 Including 18% GST

Leave A Comment