Precision Polishing Robot | Automate Your Surface Finishing

- Home

- Polishing Robot Gripper

Category

Customized Robot Gripper

Project Type

R&D and Production

Product/ Service Details

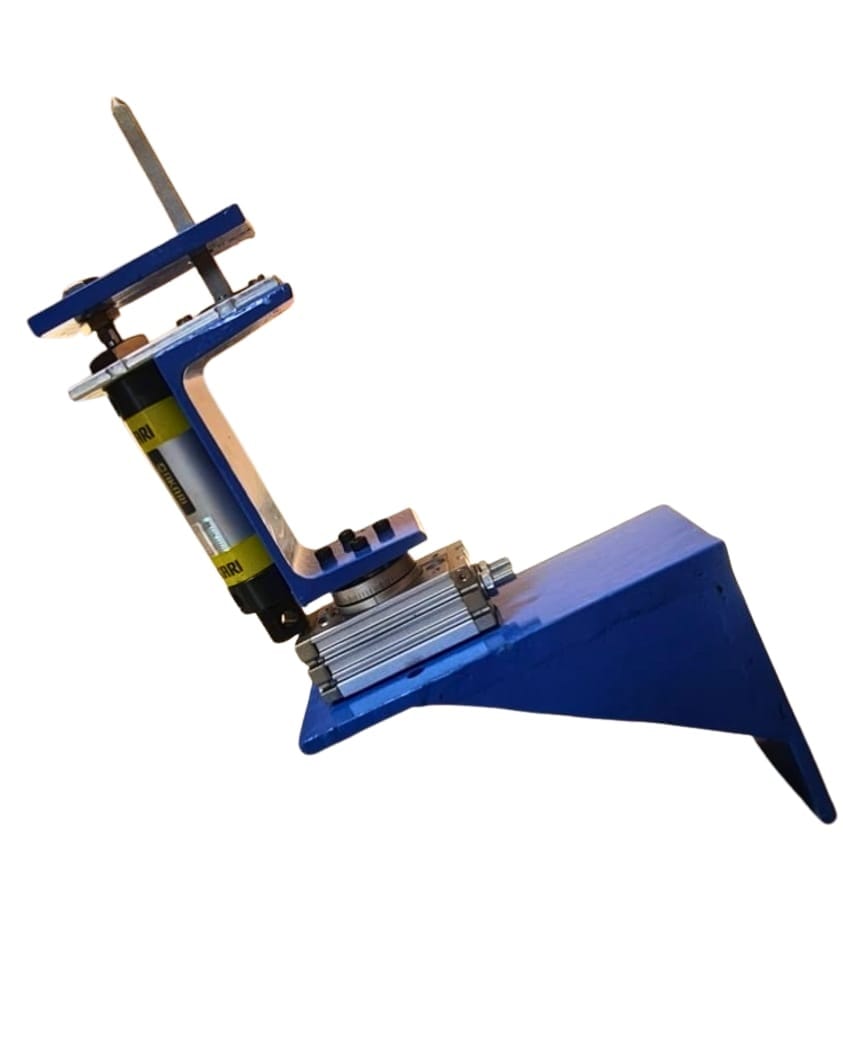

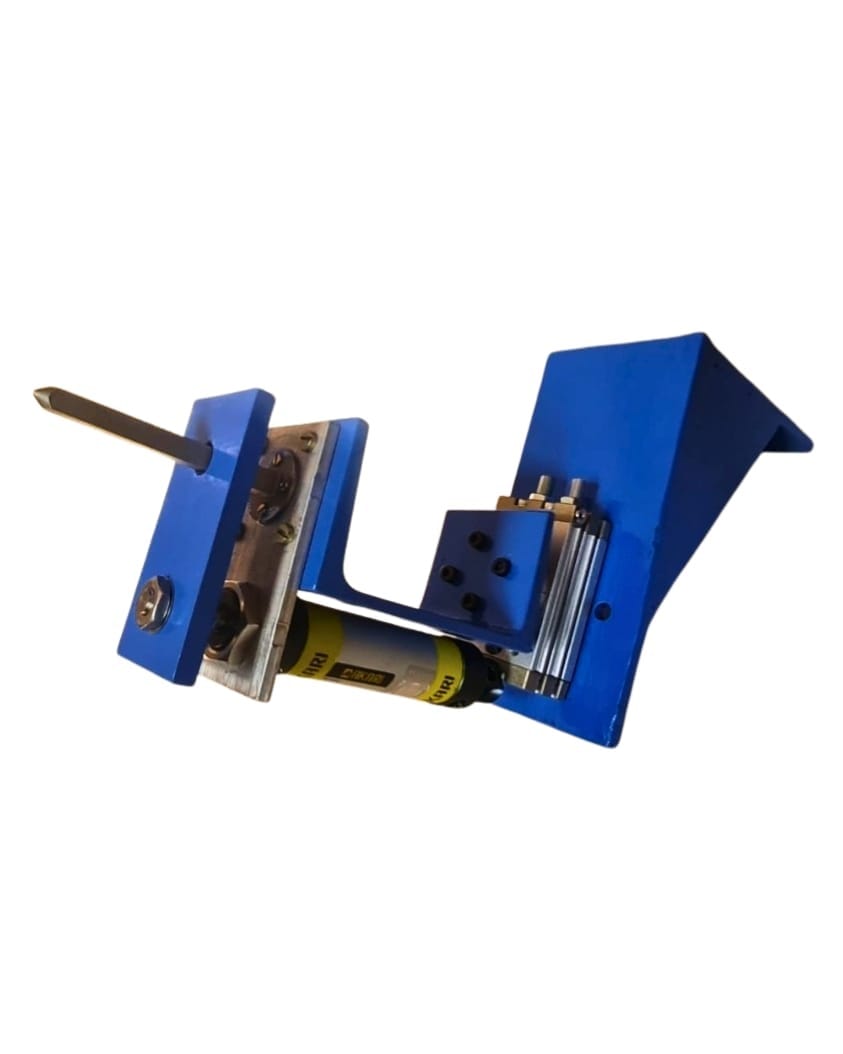

Precision Surface Engineering: Custom Robotic Polishing Gripper for Brass Door Hardware

In the luxury home hardware and interior design market, the finish of a brass door handle is a direct reflection of quality. Achieving a flawless, mirror-like polish requires robotic consistency; however, standard robotic grippers often fail to meet the specific mechanical demands of the polishing process.

Hardai ARMND Engineering Solutions has successfully designed and manufactured a specialized High-Sturdiness Robotic Polishing Gripper. This project was engineered to overcome the physical constraints and vibration challenges inherent in high-volume brass handle production.

- The Challenge

- The Innovation

- Approach

- Results

Space Constraints and Vibrational Interference

Texturing and polishing brass handles involve high-speed abrasive belts and wheels that exert significant force on the workpiece. Our client faced two critical bottlenecks:

- Confined Operational Envelope: The layout of the polishing cells required the robot to pick, polish, and drop handles within an extremely tight area. Standard bulky grippers often collided with the polishing lathes or safety enclosures.

- The "Stick-Slip" Effect: Vibration-Induced Surface Defects: Polishing creates intense mechanical vibrations. If a gripper is not perfectly rigid, these vibrations create erratic "chatter marks" or inconsistent morphological patterns on the brass surface, leading to high rejection rates in the premium interior market.

Morse Taper Design & Pneumatic Integration

To solve these issues, Hardai ARMND Engineering moved away from traditional jaw-type grippers and implemented a Morse Taper Angle design approach combined with advanced actuation.

- Morse Taper Angle for Extreme Rigidity: We utilized the principle of the Morse Taper to create a self-holding, high-precision interface. This geometry ensures that once the handle is seated, the connection is incredibly stiff. This sturdiness is the primary driver of the morphological quality of the polish—by eliminating micro-vibrations at the source, the abrasive media makes perfectly uniform contact with the brass, resulting in a superior, streak-free finish.

- Compact Profile for Confined Areas: The streamlined, tapered design significantly reduced the gripper’s footprint. This allows the robot to navigate the handle through complex polishing angles and tight machine clearances without risk of collision, maximizing the utility of the confined production space.

- Pneumatic Power Pack for Rapid De-mounting: While Morse tapers are excellent for holding, they can be difficult to release. We integrated a custom Pneumatic Power Pack system that provides a localized "kick-off" force. This ensures rapid, automated de-mounting of the handle after the polishing cycle, maintaining a high-speed production cadence.

Flexible Manufacturing Approach

At Hardai ARMND Engineering Solutions, we designed this system with a "Flexible Manufacturing" mindset. The gripper assembly features:

- Interchangeable Inserts: The gripper can be quickly adapted to accommodate different styles and geometries of door handles—from sleek modern levers to ornate traditional knobs.

- Plug-and-Play Integration: The pneumatic and mechanical interfaces are designed to fit standard industrial robot flanges, allowing for easy deployment across various robotic brands.

Superior Surface Morphology

The success of a polishing project is measured by the microscopic pattern left on the metal. Thanks to the sturdiness and vibration-damping characteristics of our Morse Taper design, our client reported:

- Zero Chatter Marks: A perfectly smooth morphological surface profile.

- Increased Throughput: Faster pick-and-place cycles in the confined workspace.

- Customer Acclaim: Our client received exceptional reviews from interior designers and home hardware distributors for the improved aesthetic consistency of the final product.