Moly Coating & Solid Film Lubricants

- Home

- Moly Coating : Superior Durability for Longer Chain Transmission Life

What is Moly Coating ?

Moly Coating is a protective layer applied to the internal components of your transmission. It’s made from molybdenum disulfide, a substance known for its exceptional lubricating properties and resistance to wear and tear. Essentially, it acts as a shield, protecting your transmission’s delicate parts from the harsh conditions they face during daily driving.

Why Choose Moly Coating ?

- Extended Transmission Life: By reducing friction and wear, Moly Coating can significantly extend the lifespan of your transmission. This means fewer repairs, lower maintenance costs, and a more reliable vehicle.

- Enhanced Performance: Moly Coating can improve your transmission’s performance by reducing heat and improving efficiency. This can lead to smoother shifts, better fuel economy, and a more enjoyable driving experience.

- Protection Against Damage: Moly Coating acts as a barrier against contaminants, preventing them from damaging the internal components of your transmission. This can help to avoid costly repairs and breakdowns.

How Does Moly Coating Work?

Moly Coating creates a smooth, protective surface on the transmission’s components. This reduces friction and prevents metal-to-metal contact, which is the primary cause of wear and tear. As a result, your transmission can operate more efficiently and reliably for a longer period.

Is Moly Coating Worth It?

If you’re looking to invest in your vehicle’s long-term health and performance, Moly Coating is definitely worth considering. While it may require an initial investment, the potential savings on future repairs and maintenance can far outweigh the cost.

Moly Coating on Chain and Sprocket: Enhancing Transmission Durability and Efficiency

In mechanical engineering, the transmission system is pivotal in transmitting power from the engine to the wheels. The chain and sprocket assembly is crucial for ensuring smooth and efficient operation among the various components within the transmission. However, these components are subjected to wear and tear due to friction and environmental factors, which can significantly reduce their lifespan and performance.

To address this challenge, the application of a molybdenum disulfide (MoS2) coating on the chain and sprocket has emerged as a promising solution. MoS2, a solid lubricant with exceptional friction-reducing properties, forms a protective layer on the metal surfaces, reducing friction and wear. This coating significantly extends the life of the transmission system and enhances its overall performance.

The benefits of Moly coating on chain and sprocket are multifaceted. Firstly, it reduces traction losses, which are energy losses that occur due to friction between the chain and sprocket. By minimizing friction, the Moly coating improves the efficiency of the transmission system, resulting in reduced fuel consumption and improved power output.

Secondly, the Moly coating protects the chain and sprocket from wear and tear. The protective layer formed by MoS2 prevents direct metal-to-metal contact, reducing the formation of abrasive particles that can damage the components. This extended lifespan translates into reduced maintenance costs and increased uptime for the transmission system.

Furthermore, the Moly coating enhances the corrosion resistance of the chain and sprocket. MoS2 is a chemically inert material that forms a barrier against moisture and corrosive elements, preventing rust and other forms of corrosion. This extended corrosion resistance ensures the longevity of the transmission system, even in harsh operating environments.

In addition to its performance benefits, Moly coating is also environmentally friendly. Unlike traditional lubricants, MoS2 is non-toxic and does not pose any environmental hazards. This makes it a sustainable solution for enhancing the durability and efficiency of transmission systems.

The application of Moly coating on chain and sprocket offers a comprehensive solution for improving the performance and lifespan of the transmission system. By reducing friction, protecting against wear and tear, and enhancing corrosion resistance, Moly coating ensures smooth and efficient operation, reduced maintenance costs, and increased uptime. As a result, it is a valuable investment for industries and applications that rely on reliable and efficient transmission systems.

Reduced Friction: Moly Coating Minimizes Traction Losses

Moly Coating on Chain and Sprocket: Enhancing Transmission Life and Minimizing Traction Losses

The application of moly coating is a relatively straightforward process. It can be applied to new or existing chains and sprockets using various methods, including spray, brush, or immersion. The coating thickness can be tailored to specific requirements, ensuring optimal performance without compromising durability.

Moly coating on chains and sprockets offers a comprehensive solution to improve transmission efficiency and longevity. By reducing friction and wear, it extends component life, minimizes traction losses, and ultimately enhances the overall performance of mechanical systems. As a result, moly coating has become an indispensable tool for engineers seeking to optimize transmission systems in a wide range of applications.

Moly coating for Chain drive

Hadai ARMND Moly Micro-Coating is a specialized treatment designed to enhance the performance and longevity of various mechanical components, particularly those involving moving parts. This coating is composed of molybdenum disulfide (MoS2), a solid lubricant known for its excellent lubricating properties and resistance to wear and tear.

Applications of Hadai ARMND Moly Micro-Coating

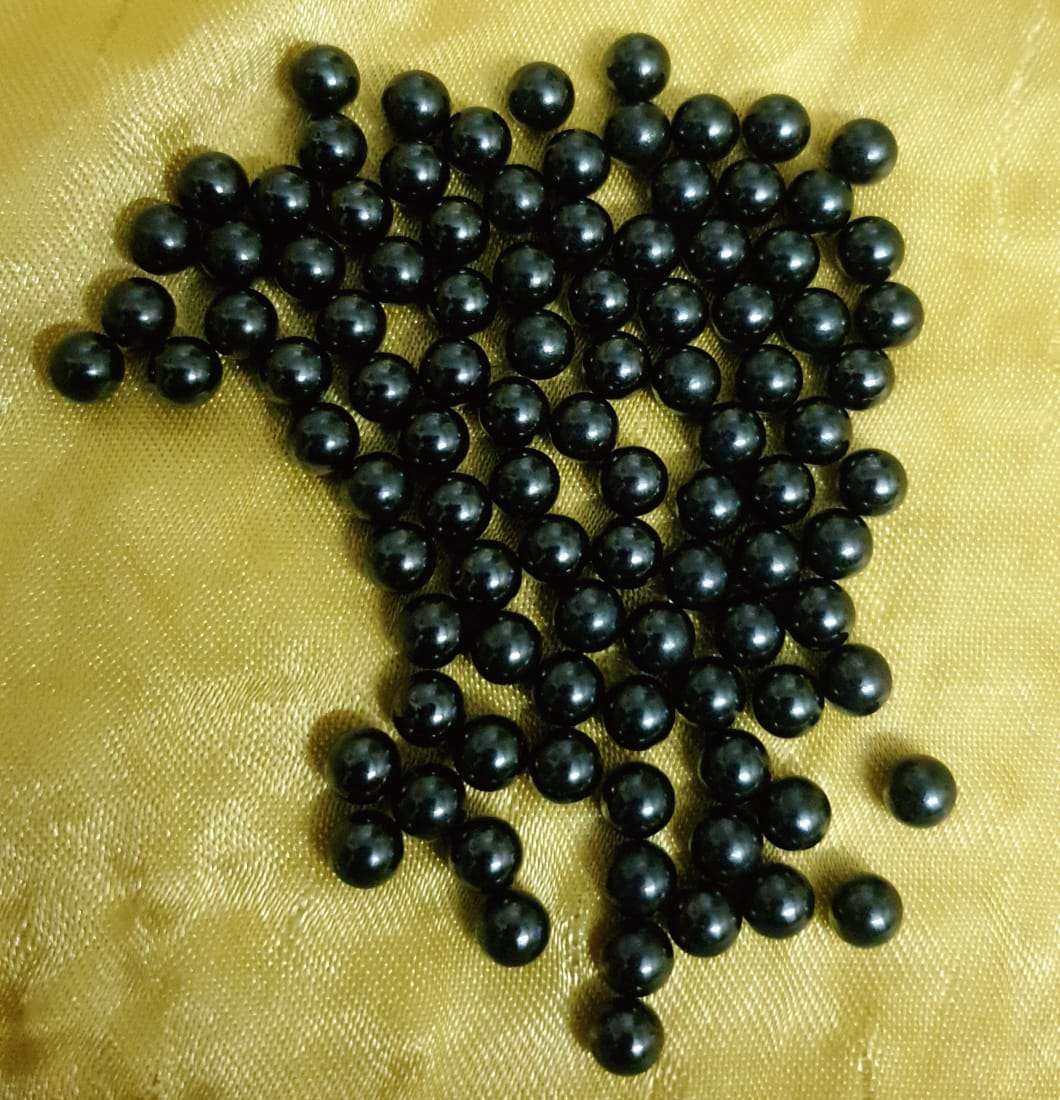

- Bearing Balls: The coating can significantly reduce friction and wear in bearing balls, leading to smoother operation, increased load capacity, and extended service life.

- Chains: Hadai ARMND Moly Micro-Coating can improve the efficiency and durability of chains used in various industries, such as automotive, manufacturing, and agriculture.

- Sprockets: By reducing friction and wear on sprockets, the coating can improve power transmission, reduce noise, and extend the lifespan of the entire drivetrain.

- Rollers: The coating can enhance the performance and durability of rollers used in various applications, such as conveyors, printing presses, and manufacturing equipment.

- Other Moving Parts: The coating can be applied to a wide range of other moving parts, including gears, cams, and shafts, to improve their performance and reliability.

Product Designer

Our Values

Hardai ARMND, a leading provider of industrial lubricants, has harnessed the power of MoS2 to create a game-changing solution for your industry. With MoS2 Dry Lubricant, you can unlock new levels of efficiency, reliability, and sustainability. Embrace this groundbreaking advancement and elevate your operations to new heights

The exceptional performance of MoS2 Dry Lubricant extends to extreme environments. It withstands high temperatures, vacuum conditions, and corrosive atmospheres, making it ideal for applications in aerospace, automotive, and chemical processing. Its ability to operate in harsh conditions reduces the need for frequent lubrication, further enhancing efficiency and reducing maintenance requirements.

Embrace the future of lubrication with Molybdenum Disulfide (MoS2) Dry Lubricant by Hardai ARMND. Experience the transformative power of this groundbreaking innovation and unlock the limitless potential of your industrial operations.

Leave A Comment