Designing Special Purpose Machines: Custom Engineering Guide

- Home

- Designing Special Purpose Machines in India: From Concept to Production-Ready Automation

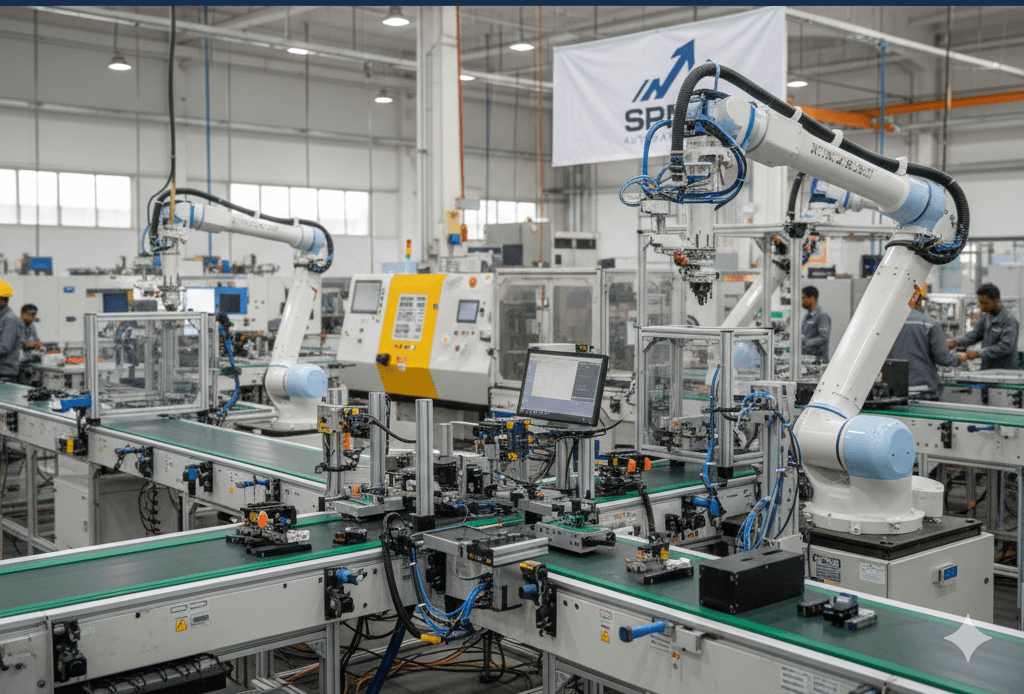

In today’s competitive manufacturing landscape, Special Purpose Machines (SPM) play a critical role in achieving high productivity, precision, and repeatability. Unlike conventional machines, special purpose machines are custom-designed to perform a specific operation or a series of operations tailored to a particular component or process.

India has emerged as a global hub for special purpose machines design and manufacturing, with strong expertise in mechanical engineering, automation, and cost-effective innovation. Cities like Pune have become well-known centers for special purpose machines manufacturers, serving industries such as automotive, heavy engineering, and industrial automation.

This blog explores the concept, design philosophy, elements, types, and examples of special purpose machines, and showcases how Hardai ARMND Engineering Solutions delivers production-ready SPM solutions for modern manufacturing.

What Are Special Purpose Machines (SPM)?

Special Purpose Machines (SPM machines) are custom-built industrial machines designed to carry out dedicated tasks such as drilling, tapping, pressing, assembly, testing, or inspection with maximum efficiency.

Unlike general-purpose machines, special purpose machines:

- Are designed for a specific product or process

- Combine multiple operations into a single automated cycle

- Reduce manpower dependency

- Improve consistency and cycle time

SPMs are widely used in automotive manufacturing, rotating equipment production, electronics, aerospace, and heavy engineering industries.

Concept of Special Purpose Machines

The core concept behind special purpose machines SPM is process-driven design. Instead of adapting a standard machine to the process, the machine is designed around the process itself.

Key objectives include:

- Eliminating unnecessary movements

- Minimizing setup and changeover time

- Increasing throughput

- Improving quality and repeatability

- Reducing production cost per part

This approach makes SPMs ideal for medium-to-high volume manufacturing environments.

General Elements of Special Purpose Machines

Every special purpose machine consists of carefully engineered subsystems that work together as one integrated solution.

1. Mechanical Structure

A rigid, vibration-free frame designed to withstand operating loads and ensure dimensional accuracy.

2. Tooling and Fixtures

Custom jigs, fixtures, and tooling designed specifically for the component being processed.

3. Actuation Systems

Hydraulic, pneumatic, servo, or electric actuators depending on force, speed, and precision requirements.

4. Control System

PLC-based control systems with HMIs for operation, monitoring, and fault diagnostics.

5. Sensors and Feedback Devices

Proximity sensors, encoders, vision systems, force and torque sensors for process validation and quality control.

6. Automation and Safety

Integrated automation with interlocks, guarding, and safety systems compliant with industrial standards.

Types of Special Purpose Machines

There are many types of special purpose machines, each designed for specific industrial applications.

Common Types of SPM Machines

- Drilling and tapping SPM

- Milling SPM

- Pressing and forming SPM

- Assembly SPM

- Leak testing machines

- Torque and force test rigs

- CNC special purpose machines

- Inspection and gauging machines

- Pick and place automation systems

Special Purpose Machines Examples

Here are some commonly used special purpose machines examples across industries:

- Multi-spindle drilling machines for automotive components

- Automated press-fit assembly machines

- Endurance test rigs for rotating components

- Hydraulic and pneumatic special purpose presses

- Functional test rigs for mechanical assemblies

- CNC-based special purpose machines for precision parts

These machines are engineered to handle high production volumes with consistent accuracy.

Special Purpose Machines in Pune and India

India is home to several special purpose machines manufacturers, with Pune being a major hub due to its strong automotive and industrial ecosystem.

Search terms such as:

- special purpose machines spm in pune

- special purpose machines in pune

reflect the region’s reputation for custom automation and SPM development.

Manufacturers in India deliver:

- Cost-effective solutions

- High engineering depth

- Global quality standards

- End-to-end support from design to commissioning

HSN Code for Special Purpose Machines

The HSN code for special purpose machines generally falls under industrial machinery and equipment categories. The hsn code for special purpose machines spm may vary depending on:

- Machine function

- Industry application

- Level of automation

Proper classification should always be confirmed during procurement, billing, and export documentation.

List of Special Purpose Machines

Below is a typical list of special purpose machines used in industrial manufacturing:

- Automotive component assembly SPM

- Rotating machines testing SPM

- Hydraulic press SPM

- CNC special purpose machines

- Special purpose test rigs

- Automated inspection machines

- Material handling SPM

- Custom production automation lines

Special Purpose Machines Design & Manufacturing by Hardai ARMND Engineering Solutions

Hardai ARMND Engineering Solutions specializes in designing and manufacturing special purpose machines that are robust, scalable, and production-ready.

Our Core SPM Services

- Concept development and feasibility study

- Detailed mechanical and automation design

- Manufacturing and assembly

- PLC programming and system integration

- Installation, commissioning, and support

Key SPM Solutions We Deliver

Automotive Manufacturing SPM

Custom machines for pressing, assembly, machining, and testing of automotive components with high repeatability and throughput.

Rotating Machines SPM

Special purpose machines and test rigs designed for rotating equipment, endurance testing, torque validation, and performance analysis.

Special Purpose Test Rigs

Advanced test rigs for force, torque, durability, and functional testing tailored to customer specifications.

CNC Special Purpose Machines

CNC-integrated SPMs for precision machining applications requiring flexibility with high production efficiency.

Our solutions are engineered to integrate seamlessly into existing production lines while ensuring long-term reliability.

Why Choose Custom Special Purpose Machines?

- Higher productivity

- Reduced operational costs

- Improved quality consistency

- Faster return on investment

- Tailored automation for complex processes

Conclusion

Special purpose machines are a cornerstone of modern manufacturing, enabling companies to achieve automation that standard machines cannot deliver. With India’s growing expertise in SPM design and manufacturing, organizations can now access world-class automation solutions built locally.

By combining deep engineering knowledge with practical manufacturing experience, Hardai ARMND Engineering Solutions transforms ideas into production-ready special purpose machines that drive efficiency, accuracy, and sustainable growth.

Recent Posts

- Ultimate Guide to Engine Oil Additives for Emergency Engine Protection & Longer Engine Life

- Clean Engines, Strong Performance: Why Drivers Trust Molykul engine oil additive

- How a Smart Engine Oil Additive Can Reduce Vehicle Emissions and Protect Urban Air Quality

- How MoS2 Grease in Stone Mining Catalyzes Superior Machine Power in India

- Cutting Downtime and Maintenance Costs in Factory Machines

Products

-

MolyKul MoS2 Gear Oil additive for cars and bike| Anti-friction MoS2 Solution - 100ml

₹507.40Original price was: ₹507.40.₹338.66Current price is: ₹338.66. Including 18% GST -

MolyKul Aero-Spec 500 (MKG AS500 NG2) – MoS2 Anti-Seize Aerospace grease – 500 Deg C ₹1,770.00 – ₹8,254.00Price range: ₹1,770.00 through ₹8,254.00 Including 18% GST

-

MolyKul MoS2 Grease for industrial application| Lithium + Anti-Seize MoS2 - 650 Deg C

₹1,305.00Original price was: ₹1,305.00.₹991.00Current price is: ₹991.00. Including 18% GST -

MolyKul MoS2 engine oil additive for cars and bikes| Anti-friction MoS2 Solution - 100ml ₹166.00 – ₹450.00Price range: ₹166.00 through ₹450.00 Including 18% GST

-

MolyKul MoS2 Grease for industrial application| Lithium + Anti-Seize MoS2 - 320 Deg C ₹580.00 – ₹5,600.00Price range: ₹580.00 through ₹5,600.00 Including 18% GST

Leave A Comment