Save Environment with MoS2 Solid-lubricants

- Home

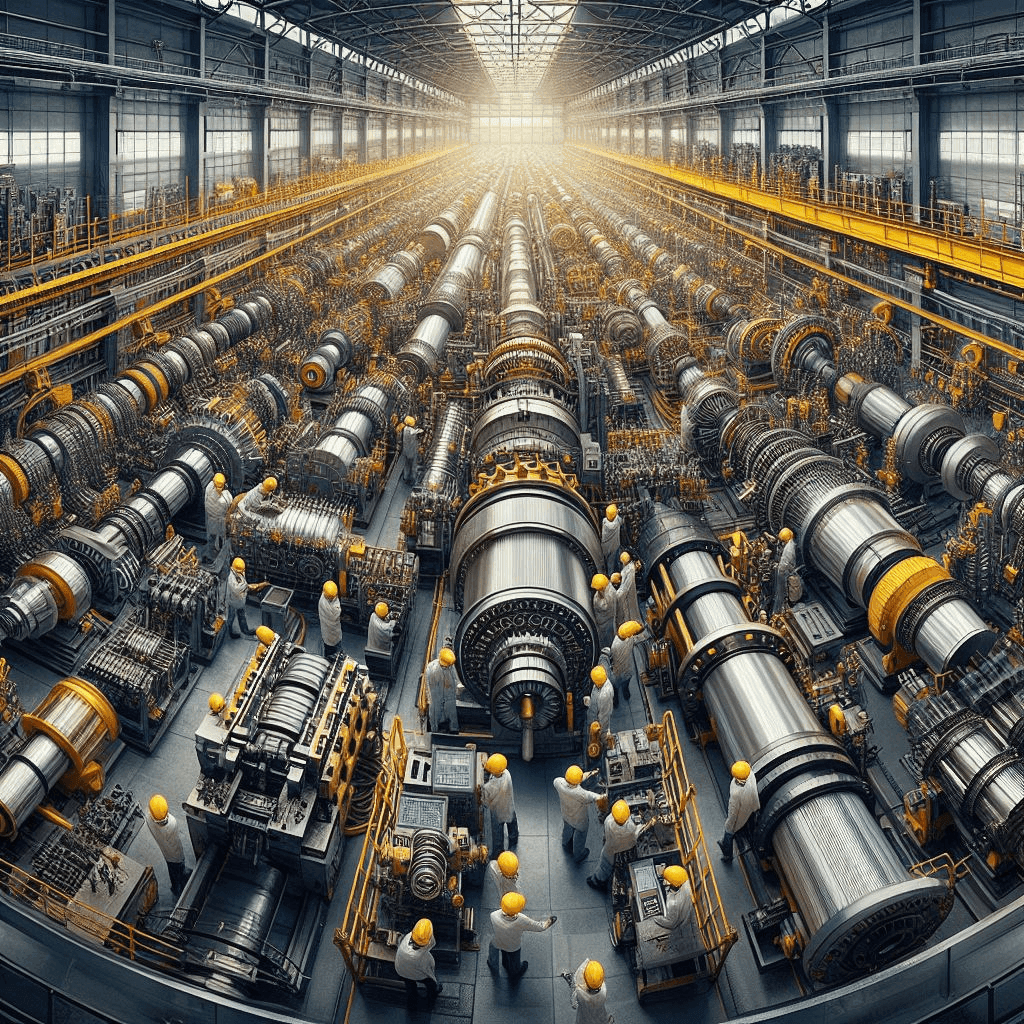

- Strong impact from industrial waste – Save Environment with MoS2

MoS2 can save the environment from industrial waste

In an era where environmental sustainability is paramount, industries face increasing pressure to minimize their ecological footprint. Among the myriad of solutions emerging, one often overlooked yet powerful ally in the fight against industrial waste is Molybdenum Disulfide (MoS2) lubrication. Let’s explore how this innovative lubrication technology not only enhances machinery performance but also plays a vital role in preserving our planet.

The Environmental Toll of Industrial Waste

Industrial operations generate vast amounts of waste, including worn-out machinery components, contaminated lubricants, and packaging materials. Improper disposal of these waste products can lead to soil, air, and water pollution, threatening ecosystems and human health. Additionally, the extraction and production of traditional lubricants contribute to greenhouse gas emissions and environmental degradation.

Enter MoS2 Lubrication: A Sustainable Solution

MoS2 lubrication offers a sustainable alternative that addresses both performance and environmental concerns. Unlike traditional lubricants, MoS2 forms a solid, low-friction layer on machinery surfaces, reducing the need for frequent reapplication and minimizing waste generation. This durability extends machinery lifespan, further reducing the disposal of worn-out components.

Minimizing Lubricant Waste

One of the most significant environmental benefits of MoS2 lubrication lies in its longevity and efficiency. Traditional lubricants often require frequent replenishment due to degradation and contamination, resulting in the disposal of used oils and lubricants. In contrast, MoS2 lubricants remain effective for extended periods, reducing the frequency of lubricant changes and minimizing waste generation.

Preventing Machinery Wear and Tear

By forming a protective barrier against friction and wear, MoS2 lubrication mitigates the premature degradation of machinery components. This not only extends equipment lifespan but also reduces the frequency of replacements, thereby curbing the disposal of worn-out parts and contributing to resource conservation.

Energy Efficiency and Emissions Reduction

Furthermore, MoS2 lubrication enhances energy efficiency by reducing friction and optimizing machinery performance. This results in lower energy consumption, reducing the reliance on fossil fuels and decreasing greenhouse gas emissions. By promoting energy-efficient operations, MoS2 lubrication helps industries minimize their carbon footprint and mitigate climate change.

LESS INDUSTRIAL WASTE ECOSYSTEM

Case Study: MoS2 in Action

Consider a manufacturing plant that implemented MoS2 lubrication across its machinery fleet. By switching to MoS2 lubricants, the plant reduced lubricant consumption by 30%, extended equipment lifespan by 20%, and decreased energy consumption by 15%. These environmental benefits not only contribute to a healthier planet but also translate into substantial cost savings and enhanced sustainability for the business.

Undoubtedly MoS2 lubrication stands as a beacon of hope in the quest for environmental sustainability within industry. By minimizing waste generation, conserving resources, and promoting energy efficiency, MoS2 lubrication offers a holistic solution that benefits both businesses and the environment. As industries strive to adopt greener practices, integrating MoS2 lubrication into their operations emerges as a crucial step towards building a more sustainable future for generations to come.

FAQ’s

- How does MoS2 lubrication contribute to environmental sustainability? MoS2 lubrication minimizes waste generation by extending machinery lifespan and reducing the frequency of lubricant changes, thus decreasing the disposal of used oils and lubricants.

- Does MoS2 lubrication help in preventing machinery wear and tear? Yes, MoS2 forms a protective barrier against friction and wear, which not only extends equipment lifespan but also reduces the disposal of worn-out machinery components.

- How does MoS2 lubrication promote energy efficiency and emissions reduction? By reducing friction and optimizing machinery performance, MoS2 lubrication lowers energy consumption, decreasing reliance on fossil fuels and mitigating greenhouse gas emissions.

- Are there any real-world examples of the environmental benefits of MoS2 lubrication? Yes, industries implementing MoS2 lubrication have reported significant reductions in waste generation, resource consumption, and energy usage, contributing to enhanced environmental sustainability.

- Does MoS2 lubrication offer cost-effective solutions for businesses concerned about environmental impact? Absolutely, the longevity and efficiency of MoS2 lubricants lead to cost savings through reduced lubricant consumption, maintenance, and energy expenses, making it an economically and environmentally viable choice for businesses.

Leave A Comment