End of Arm Tooling (EOAT) Design & Manufacturing Solutions

- Home

- End Of Arm Tooling (EOAT)

Category

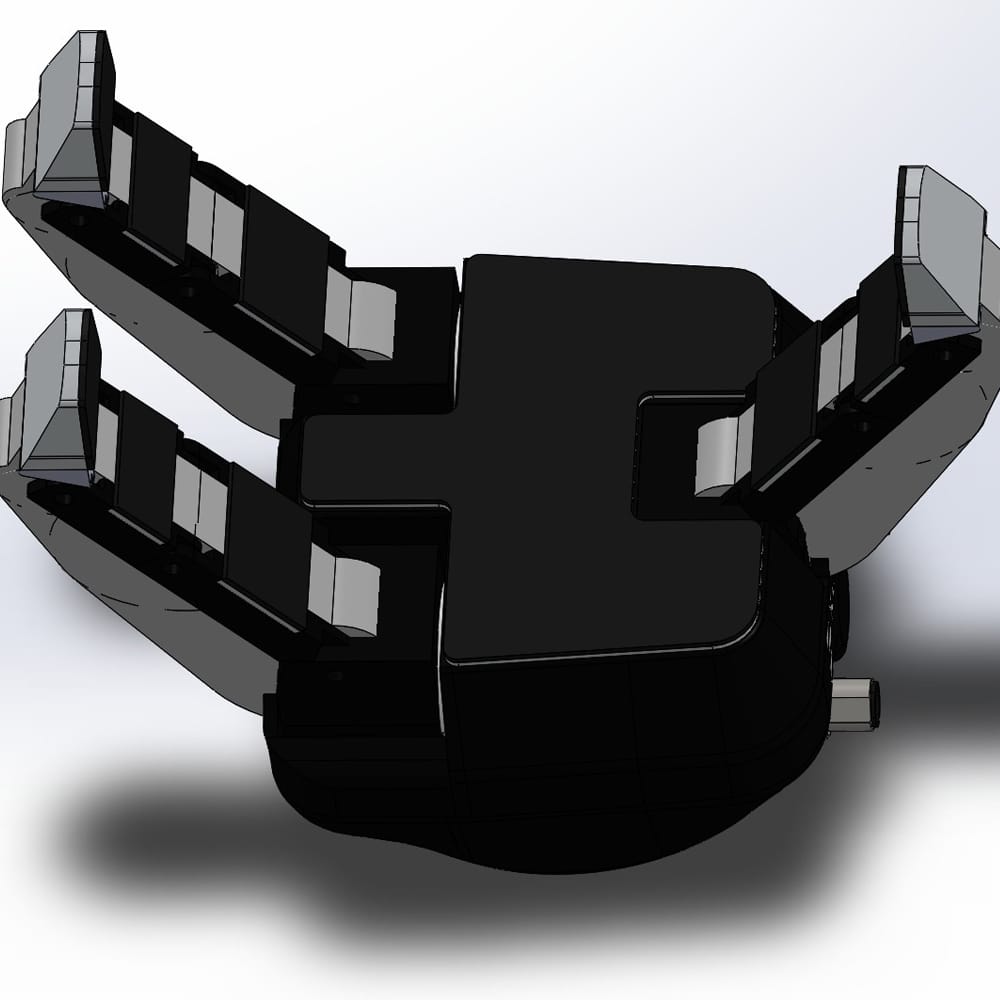

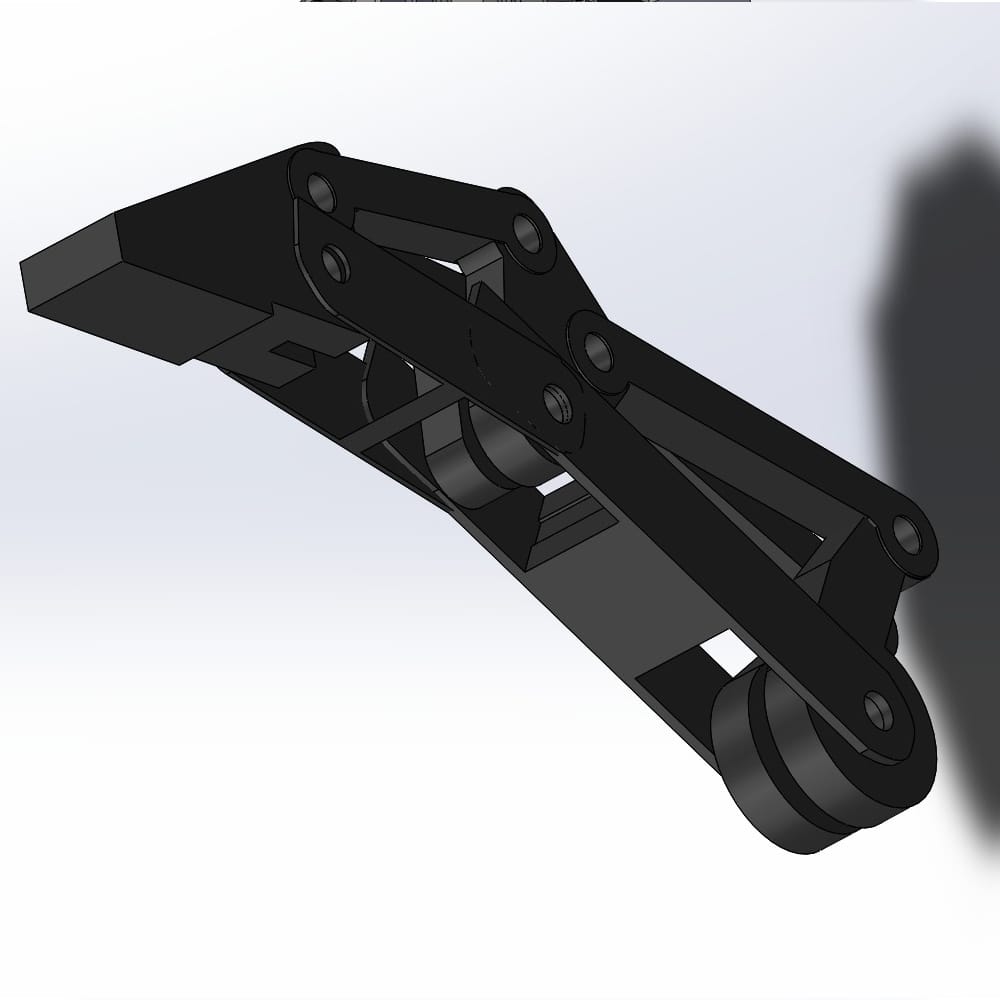

Customized robot gripper

Service type

R&D and production

Product/ Service Details

What is End Of Arm Tooling (EOAT) ?

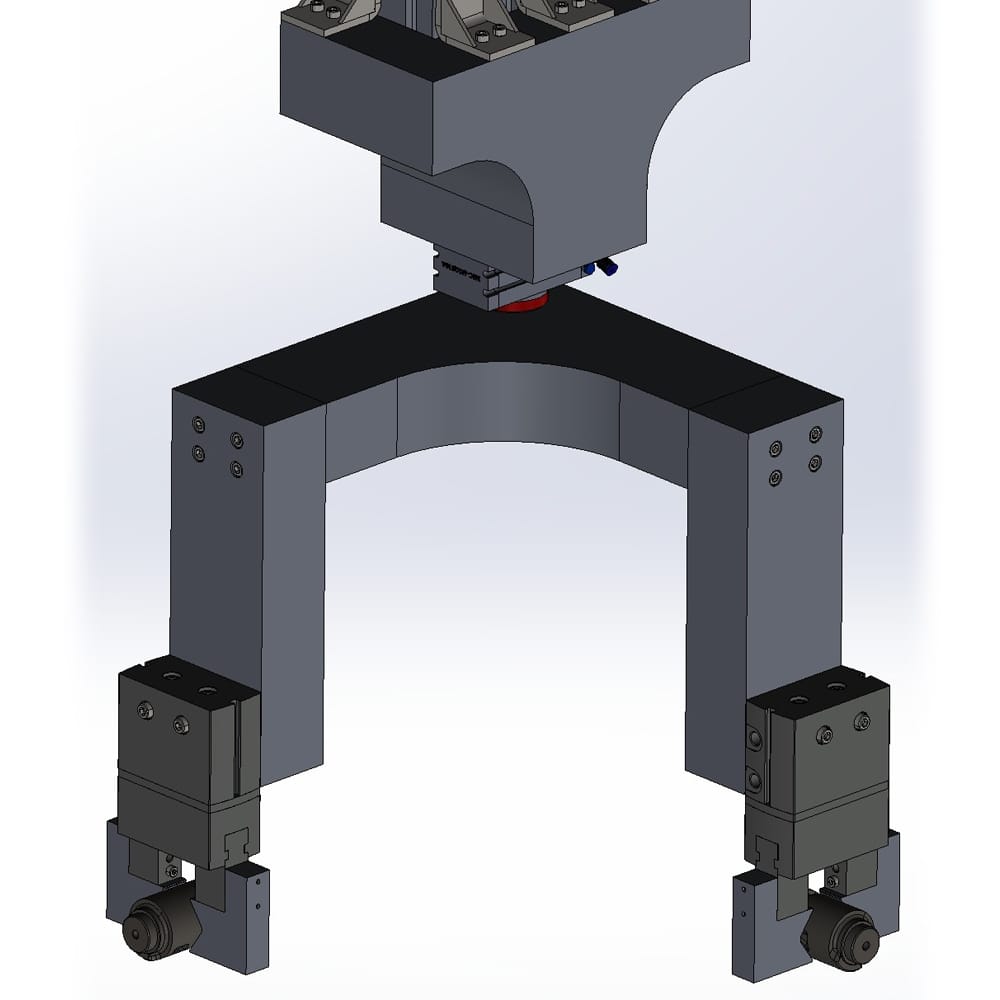

EOAT (End of Arm Tooling)refers to the custom-designed device mounted on a robot’s wrist to interact with parts or tools. The EOAT meaning in automation lies in enabling precise handling, gripping, or processing. At Hardai ARMND Engineering Solutions, we specialize in EOAT design and manufacturing of EOAT robot systems including EOAT gripper, robot EOAT gripper, vacuum EOAT, and specialized EOAT tooling. Our solutions integrate optimized EOAT components, load calculations, and EOAT quick change systems to ensure flexibility, accuracy, and productivity across diverse industrial applications.

- Need of EOAT Designing

- Types of EOAT

- 3D CAD Modeling

- EOAT Services

Need of EOAT Designing

EOAT designing is essential to ensure a robot can handle, grip, move, or process parts accurately and safely. A well-designed End of Arm Tooling improves precision, reduces cycle time, and prevents product damage. Customized EOAT design considers part geometry, weight, material, and process requirements, ensuring optimal performance. Proper EOAT designing also enhances flexibility through quick-change systems, increases operator safety, and maximizes robot utilization. For applications like pick-and-place, assembly, welding, or material handling, tailored EOAT is critical to achieving consistent quality, higher productivity, and reliable automation performance.

Types of EOAT (End of Arm Tooling)

EOATs are selected based on application, payload, and process needs. Common types of EOAT include:

- Gripper EOAT: Mechanical or servo-driven EOAT gripper for precise part handling.

- Vacuum EOAT: Uses suction cups for lightweight, flat, or delicate components.

- Magnetic EOAT: Ideal for ferrous materials like sheets and billets.

- Tool EOAT: Includes welding guns, screwdrivers, dispensers, and cutters.

- Adaptive/Soft EOAT: Flexible grippers for varied shapes and fragile parts.

- EOAT Quick Change Systems: Enable rapid tool swaps to improve uptime.

- Inspection EOAT: Cameras, sensors, and probes for quality checks.

Introduction to 3D CAD Modeling

3D CAD Modeling is the process of creating accurate three-dimensional digital representations of components, assemblies, and systems using computer-aided design software. It enables engineers to visualize concepts, validate form and fit, and optimize functionality before manufacturing. In industrial applications, 3D CAD modeling improves design accuracy, reduces development time, and minimizes errors. It plays a critical role in product development, automation solutions, tooling, and custom machine design by supporting simulations, interference checks, and seamless transition from design to manufacturing

EOAT services by Hardai ARMND

EOAT Services focus on the design, engineering, and manufacturing of customized End of Arm Tooling solutions that enhance robotic performance and productivity. These services ensure the robot is equipped with the right gripper or tool for accurate handling, assembly, or processing, tailored to specific applications, payloads, and cycle time requirements.

- EOAT CAD Design: It involves creating precise 3D models of end of arm tooling to ensure optimal grip, load balance, reach, and seamless integration with robotic systems before manufacturing.

- EOAT Manufacturing and Development: It involves designing, engineering, and producing customized end-of-arm tooling that ensures precise, reliable, and efficient robotic handling for specific industrial applications.

Let’s Collaborate with Hardai ARMND on Your Next Project

Unlock innovation and efficiency with Hardai ARMND as your engineering partner. Whether you’re exploring robotics, automation, or specialized manufacturing solutions, we’re ready to tailor our expertise to your project needs