High-Performance MoS2 Solid Lubricant

- Home

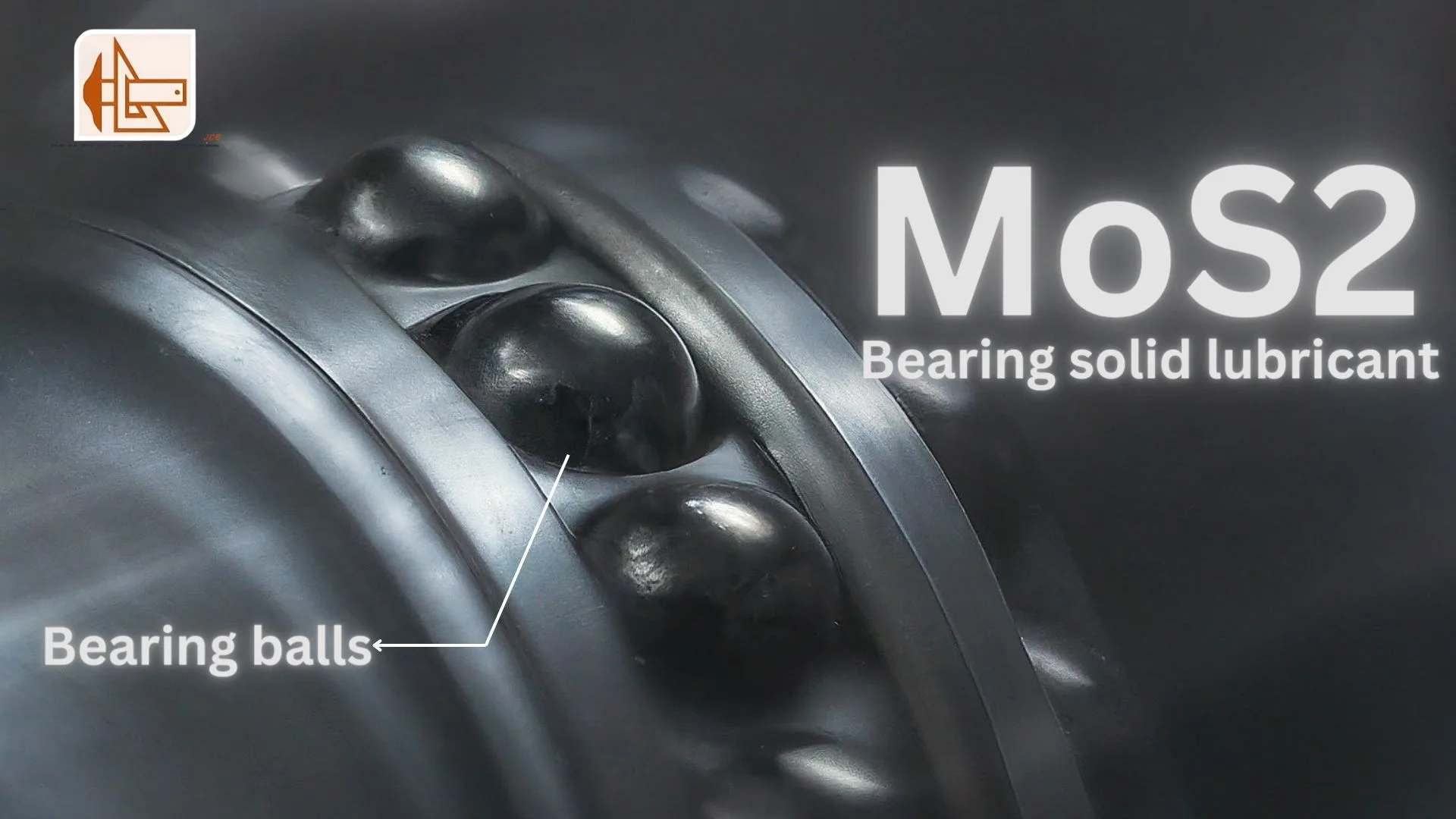

- Precision bearing big life support – MoS2 solid lubricant

Introduction to MoS2 solid lubricant

Precision bearings are an integral part of various machinery and equipment, enabling smooth and efficient operation. The demand for high-performance bearings that can withstand extreme conditions and offer extended service life has led to continuous research and development in the field. One such advancement is the application of MoS2 Solid Lubricant coating, which has proven to be a game-changer for precision bearing applications.

Molybdenum Di Sulfide (MoS2) for precision bearing

What is MoS2 Solid Lubricant Coating?

MoS2, or molybdenum disulfide, is an inorganic compound known for its excellent lubricating properties. When used as a MoS2 Solid Lubricant coating, MoS2 forms a thin film on the bearing surface, providing a durable and low-friction barrier that significantly reduces wear and tear. This coating is highly resistant to extreme temperatures, pressures, and corrosive environments, making it ideal for demanding applications.

Advantages of MoS2 Solid Lubricant Coating for Precision Bearing

- Enhanced durability: The MoS2 coating extends the lifespan of precision bearings by minimizing wear and friction, leading to less frequent replacements and reduced maintenance costs.

- Improved performance: The low-friction properties of MoS2 enable smoother operation and reduce heat generation, leading to more efficient and reliable performance in high-speed and heavy-duty applications.

- Extreme condition resistance: MoS2 coatings are highly resistant to temperature fluctuations, high pressures, and corrosive substances, ensuring optimal bearing performance even in harsh environments.

- Energy efficiency: Reduced friction leads to lower energy consumption, making MoS2-coated precision bearings an eco-friendly choice.

- Versatility: MoS2 coatings can be applied to various bearing types, sizes, and materials, making them suitable for a wide range of precision bearing applications.

Applications of MoS2 Solid Lubricant Coating in Precision Bearing

MoS2 solid lubricant coatings have proven beneficial in several precision bearing applications, including:

- Aerospace and aviation: Precision bearings in aircraft engines, landing gear, and control systems require high reliability and durability, which MoS2 coatings provide.

- Automotive: MoS2-coated precision bearings are used in various automotive components, such as transmissions, wheel hubs, and engine accessories, to ensure smooth operation and extended service life.

- Medical devices: Precision bearings in medical equipment, like surgical tools and imaging devices, benefit from the low-friction and durable properties of MoS2 coatings.

- Industrial machinery: In manufacturing, mining, and construction equipment, MoS2-coated precision bearings contribute to increased efficiency and reduced maintenance costs.

Conclusion

MoS2 solid lubricant coating offers a significant advancement in the field of precision bearings, providing enhanced performance, durability, and energy efficiency. With its ability to withstand extreme conditions and wide range of applications, MoS2 coating is a smart investment for industries seeking to improve the reliability and longevity of their precision bearing systems. As technology continues to evolve, we can expect further innovations in solid lubricant coatings, leading to even more efficient and sustainable solutions for precision bearing applications.

FAQ’s

- Q: What are precision bearings, and where are they used?

A: Precision bearings are high-quality, accurately-manufactured bearings designed to minimize friction and support smooth, efficient motion in various applications. They are commonly used in industries such as automotive, aerospace, medical, and industrial machinery where high performance and reliability are critical.

- Q: What is MoS2 solid lubricant coating, and what are its benefits?

A: MoS2 (molybdenum disulfide) solid lubricant coating is an extremely thin layer of lubricating material applied to bearing surfaces. It offers several benefits, including reduced friction, increased wear resistance, improved energy efficiency, and enhanced durability in extreme conditions.

- Q: How does MoS2 coating improve the performance of precision bearings?

A: MoS2 coating reduces friction between the bearing components, leading to smoother operation, lower heat generation, and reduced wear. This results in higher efficiency, increased reliability, and extended lifespan for precision bearings, especially under demanding operating conditions.

- Q: Can MoS2 coating be applied to different types of precision bearings?

A: Yes, MoS2 coating can be applied to various types of precision bearings, such as ball bearings, roller bearings, and needle bearings, made from different materials like steel, ceramic, or other specialized alloys. This versatility makes it suitable for a wide range of applications.

- Q: Are there any environmental benefits associated with using MoS2-coated precision bearings?

A: Yes, MoS2-coated precision bearings can lead to environmental benefits. Reduced friction results in lower energy consumption, leading to decreased greenhouse gas emissions. Additionally, the extended lifespan of MoS2-coated bearings reduces waste and the need for frequent replacements, contributing to a more sustainable and eco-friendly solution.

Leave A Comment