MolyKul MoS2 Bearings – Heavy-Duty Industrial Bearings

- Home

- MolyKul Spin

MoS2 Coated Bearing product: MolyKul Spin

- Oil free and grease free bearings

- Secondary lubrication supported bearings

- Temperature resistant bearings

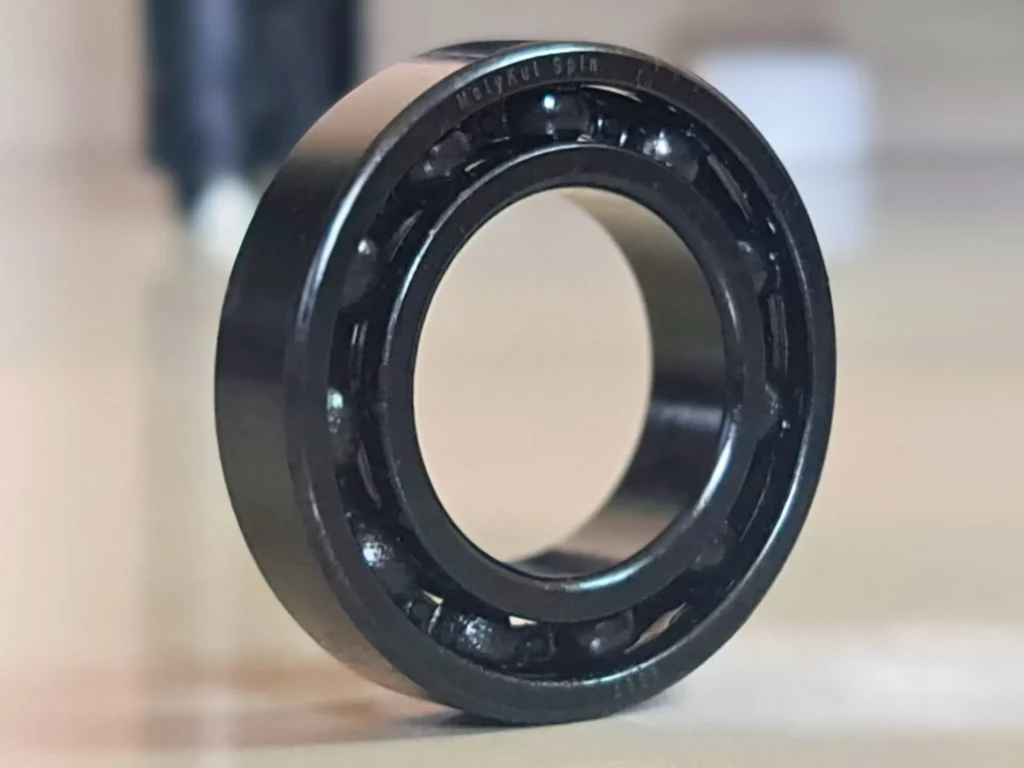

MolyKul Spin bearings leverage the power of Molybdenum Disulfide Dry Lubrication Coating technology and specialized additives. MoS2’s exceptional lubricating properties significantly reduce friction and wear, forming a protective layer on bearing surfaces that prevents metal-to-metal contact. This innovative approach leads to a multitude of benefits:

- Reduced Energy Consumption: Minimize energy usage and lower operational costs.

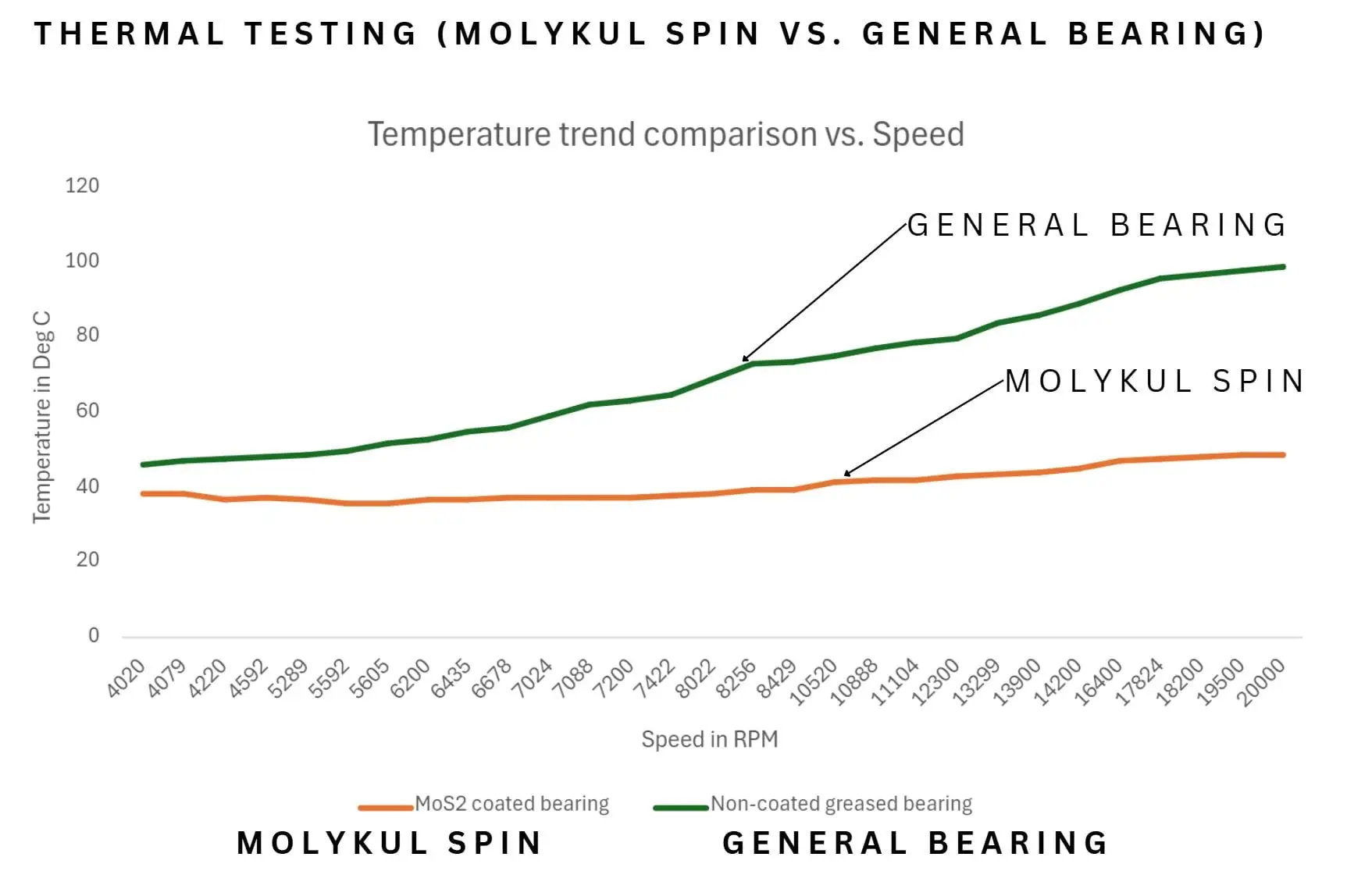

- Lowered Heat Generation: Reduce thermal stress on bearings, enhancing their durability.

- Noise and Vibration Reduction: Create smoother, quieter operations.

- Enhanced Corrosion Resistance: Protect bearings from harsh environments, extending their lifespan.

MolyKul Spin by HAES

MolyKul Spin – AP

All the components of bearings are coated with a Micro-thin Moly Dry Lubricant Compound. These bearings are used where the ambient is dry or monstrous.

MolyKul Spin – B

Only the Balls of the Bearing are coated with a Micro-thin Moly Dry Lubricant Compound. These Bearings are used where the ambient contains oil.

MolyKul Spin – CB

The Balls and cage are coated with a Micro-thin Moly Dry Lubricant Compound. These Bearings are used where a strong flow of abrasives is present in the ambient

Versatility and Compatibility

High temperature bearings india are highly versatile and compatible with various lubricants, making them suitable for a wide range of demanding industrial applications. Rigorous independent testing has demonstrated substantial reductions in friction and wear, leading to increased efficiency and extended component life.

Experience the Difference

By incorporating MolyKul Spin into your operations, you can expect a minimum of 15% reduction in energy consumption for electric motors alone. Elevate your industrial and aerospace applications with MolyKul Spin, the future of bearing technology.

Key Features

- Superior Lubrication: Minimizes friction and wear, leading to extended component life.

- Exceptional Anti-Seize Properties: Prevent galling and seizing, even in extreme conditions.

- Excellent Corrosion Resistance: Protect bearings from harsh environments and corrosive agents.

- Enhanced Performance: Improves efficiency and reduces energy consumption.

- Reduced Maintenance Costs: Lower maintenance costs and downtime.

Industrial Strength: MoS2 Solid Lubricant Coated Bearings

MolyKul Spin: Revolutionizing Bearing Performance

MolyKul Spin’s MoS2-coated bearings offer a revolutionary approach to bearing technology. With a specialized application of MoS2 coating on the balls, cage, and inner ring, these bearings are oil-free and self-lubricating, ensuring extended operational life.

Key Benefits:

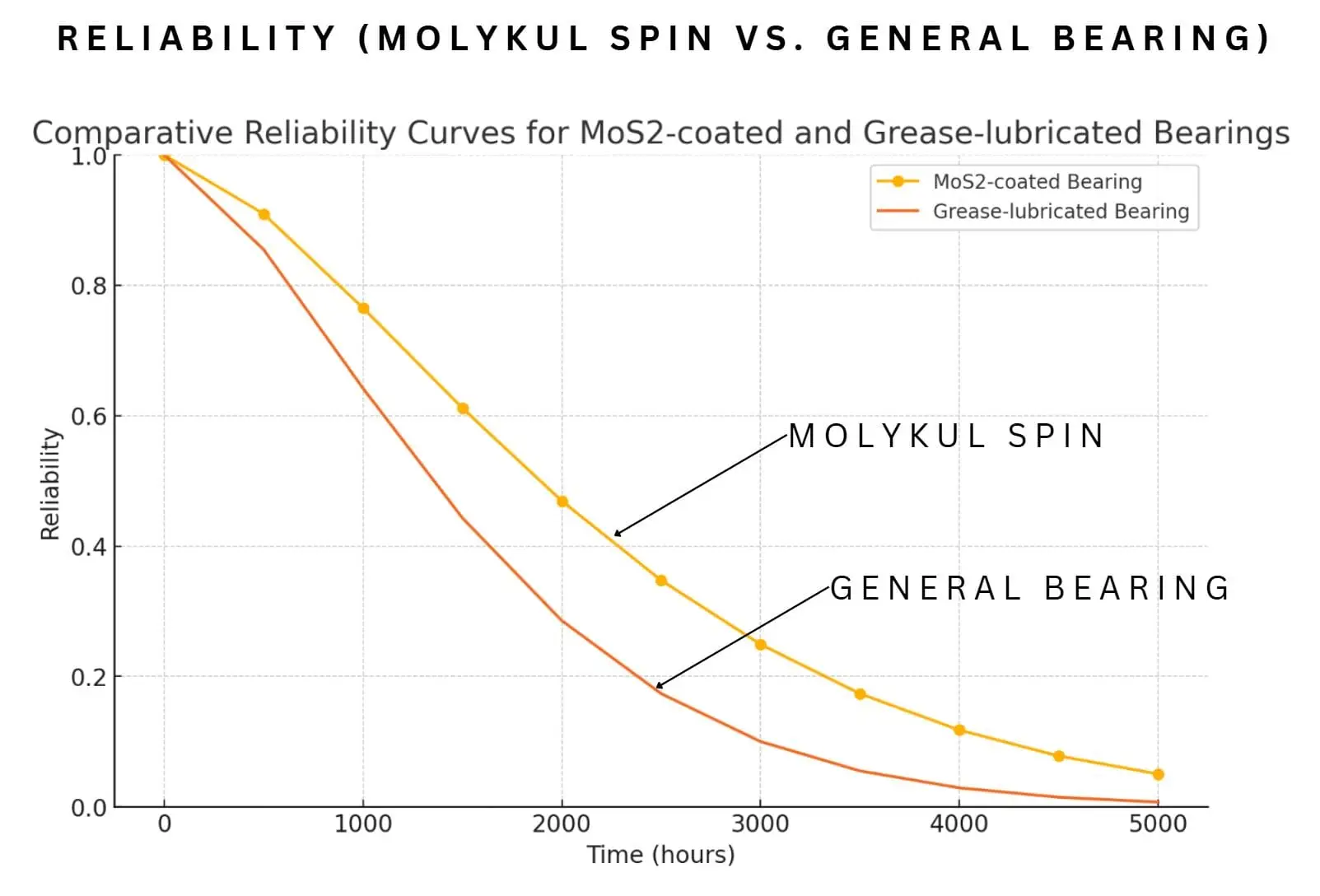

- Extended L50 Life: Significantly increases the bearing’s lifespan.

- Enhanced Durability and Reliability: Deliver exceptional performance in demanding applications.

- Oil-Free Operation: Reduce maintenance requirements and environmental impact.

- Self-Lubrication: Ensure smooth and efficient operation.

MolyKul Spin, an innovative Molybdenum Disulfide coated bearing product from Hardai ARMND Engineering Solutions, has emerged as a game-changer in the aerospace and industrial sectors. This advanced coating technology offers exceptional benefits for various components, including electric motors, pumps, compressors, conveyor belts, and numerous bearing applications.

MoS2 low-friction coating reduces wear, extends component life, and improves efficiency. In aerospace, it withstands extreme conditions in aircraft engines and landing gear. In industry, it enhances electric motors, pumps, conveyor belts, and bearings, reducing friction, noise, and maintenance costs. The versatile coating can be applied easily and adheres strongly to metal surfaces, ensuring long-lasting protection. MolyKul Spin enhances performance, safety, and durability in demanding applications where reliability and efficiency are crucial.

Industries where MolyKul Spin is higly needed and benificial

- Conveyor systems: Conveyor systems, crucial across diverse industries like food processing, sugar-cane crushing, stone and cement processing, mining, waste management, automation, robotics, pharmaceuticals, and metal forming, demand precision, continuous duty cycles, and often, stringent cleanliness standards alongside heavy-duty performance. In these demanding environments, downtime and maintenance become critical concerns. MolyKul Spin emerges as the ideal solution, engineered to optimize conveyor operation by significantly reducing downtime and maintenance requirements. Its formulation ensures continuous duty cycles, delivering the precise output necessary for consistent and efficient production. Whether handling delicate food items or rugged mining materials, MolyKul Spin’s superior lubrication properties minimize friction, wear, and tear, extending the lifespan of conveyor components and maximizing operational efficiency. This translates to enhanced productivity, reduced operational costs, and reliable performance across all applications. Conatct Us for more information.

- Electric Motors: The escalating demand for electric motors is outpacing technological advancements, leading to premature failures as manufacturers rely on outdated technologies to meet high production volumes. This stagnation necessitates a cost-effective solution to enhance motor performance and longevity. MolyKul Spin represents a significant technological leap, offering a small investment with substantial returns. Its advanced formulation addresses the critical challenges faced by electric motors across diverse applications, including EV vehicles, manufacturing equipment, conveyors, spindles, alternators, generators, escalators, lifts, pumps, compressors, industrial fans, coolers, and vacuum machines. By minimizing friction, reducing wear, and optimizing heat dissipation, MolyKul Spin extends motor lifespan, improves efficiency, and ensures reliable operation, effectively bridging the gap between current motor technology and the demands of modern applications. Conatct Us for more information.

- Pumps and compressors:Bearings within centrifugal pumps, crankshafts of pumps and compressors, swash plates of piston pumps and compressors, screw pumps, chiller pumps, and heat pumps endure constant, extreme temperature fluctuations and moisture exposure, leading to premature failure of conventional lubrication and escalating maintenance costs and downtime. To address this critical issue, OEMs can revolutionize their product offerings by integrating MolyKul Spin. This advanced lubricant is specifically engineered to withstand these harsh operating conditions, providing superior protection against wear, corrosion, and thermal degradation. By incorporating MolyKul Spin, OEMs not only enhance the reliability and longevity of their equipment but also create a significant competitive advantage, marking a new milestone in business development by delivering a product that minimizes user downtime and significantly reduces overall operational expenses. Conatct Us for more information.

- High speed turbomachines: High-speed turbomachines, operating under intense thermal loads and rapid rotations, are plagued by two primary lubrication challenges: inconsistent lubricant pressure due to thermal variations and counter-drag caused by lubricant mist formation. MolyKul Spin offers a groundbreaking solution by leveraging the exceptional properties of MoS2 dry lubrication. By utilizing MolyKul Spin, approximately 80% of the lubrication requirements can be met through its robust dry film, minimizing the reliance on conventional oil or grease. The remaining 20% can be supplemented with low-pressure lubrication oil, drastically reducing thermal loads and pressure variations within the turbomachine. This approach effectively eliminates lubricant mist, significantly decreasing counter-drag and enhancing overall efficiency. The result is a substantial reduction in thermal stress, improved lubricant consistency, and optimized performance, leading to increased reliability and longevity of high-speed turbomachinery. Conatct Us for more information.

- Aerospace and defense machines & flights: Defense and aerospace bearings operate under extreme temperature and pressure conditions, demanding unparalleled reliability. Traditional lubrication methods often fall short in these harsh environments, as lubricants can degrade or fail under such intense stress. MolyKul Spin, utilizing MoS2 dry lubrication, provides a robust and reliable solution that transcends these limitations. Its dry film formulation maintains its lubricating properties across a wide range of extreme temperatures and pressures, ensuring consistent performance and minimizing the risk of failure. This inherent resilience makes MolyKul Spin ideal for critical defense and aerospace applications, where reliability is paramount and conventional lubrication practices are inadequate. By providing a dependable barrier against wear and friction, MolyKul Spin enhances the longevity and performance of vital components, ensuring mission success and operational safety. Conatct Us for more information.

- Spindle applications: CNC machine spindles, critical for high-precision and high-speed machining, typically rely on expensive ceramic bearings to meet performance demands. This limits cost-effective manufacturing of medium and low-cost CNC machines, leaving a significant gap in the market. MolyKul Spin presents a viable and economical alternative for these applications. By utilizing MolyKul Spin’s MoS2 dry lubrication technology, manufacturers can achieve comparable performance levels without the high cost associated with ceramic bearings. This allows for the production of medium to low-cost CNC machines that maintain precision and speed, making them more accessible to a wider range of users. MolyKul Spin’s ability to minimize friction and wear, even at high speeds, ensures reliable spindle operation and extends component lifespan, providing a cost-effective solution that doesn’t compromise on quality or performance. OEM can Conatct Us for more information.

- Textile machineries: Textile machinery, operating under continuous duty cycles, necessitates highly reliable bearings to minimize maintenance and downtime. 1 Conventional lubrication methods often fail to meet these demanding requirements, leading to frequent interruptions and increased operational costs. MolyKul Spin bearings, featuring MoS2 dry lubrication, offer a significant advantage, delivering up to four times the duty cycle of traditional bearings. This enhanced performance translates to reduced maintenance intervals, minimized downtime, and increased productivity. The robust dry film of MoS2 provides superior protection against wear and friction, ensuring consistent and reliable operation even under the demanding conditions of textile manufacturing. By adopting MolyKul Spin, textile machinery manufacturers and operators can achieve significant improvements in efficiency and cost-effectiveness. Conatct Us for more information.

- Racing Automotive bearing applications: Racing automotive bearings, found in engine crankshafts, camshafts, steering systems, gear shifters, gearboxes, and wheels, are subjected to extreme impact loads and torques during sudden, high-speed starts. Conventional lubrication methods often prove costly and unreliable in these demanding conditions. MolyKul Spin, with its MoS2 dry lubrication coating, offers a superior solution. Unlike conventional lubricants that require rotation to form a lubricating film, MolyKul Spin’s MoS2 layer provides an “infinite” lubrication surface, immediately protecting bearings from wear and impact, even during the most abrupt accelerations. This inherent characteristic allows MolyKul Spin to effectively handle the intense impact loads and torques encountered in racing applications, ensuring consistent performance and extending component lifespan. By eliminating the need for a fluid film to develop, MolyKul Spin minimizes wear during critical start-up phases, providing a more reliable and cost-effective lubrication solution for high-performance racing vehicles. Conatct Us for more information.

- Gearbox applications: Gearboxes, responsible for transmitting constant power to the transmission, can experience power inconsistencies due to gear vibrations. These vibrations often stem from bearing wear, which in turn is exacerbated by inconsistent lubrication film supply. MolyKul Spin addresses this issue with its MoS2 dry lubrication film, providing a continuous and “infinite” lubricating layer to the bearings. This eliminates the variability in lubrication that leads to bearing wear, effectively minimizing gear vibrations. By maintaining consistent lubrication, MolyKul Spin ensures smooth and reliable power transmission, preventing gearbox vibrations and enhancing the overall performance and longevity of the system. This consistent lubrication leads to more stable power transfer, and a reduction in unwanted noise and vibration. Conatct Us for more information.

- Ocillating motions & Micro-movement motions: Oscillating and micro-movement motions present a unique lubrication challenge, as they lack sufficient rotation to establish a consistent lubricating film with conventional lubricants. This leads to increased metal-to-metal contact and accelerated surface wear over time. MolyKul Spin, with its MoS2 dry lubrication, provides a solution by offering an “infinite” lubricating layer. Unlike traditional lubricants that rely on fluid motion, MoS2 forms a durable, solid film that effectively minimizes friction and wear even in the absence of significant rotation. This makes MolyKul Spin ideal for applications involving micro-movements and oscillations, where it ensures consistent lubrication and protects surfaces from premature wear, extending the lifespan of components and enhancing overall system reliability. Conatct Us for more information.

What Our Client Says About Us

Atmanirbhar nanotech| Dry-Lube Bearings

Unlocking the future of lubrication with MoS2 Dry Lubricated Bearings and the revolutionary MolyKul Spin! Dive deep into the world of Atmanirbhar nanotechnology pioneered by Hardai ARMND and discover how MoS2 nanotechnology is transforming dry lubrication. Learn about the innovative MolyKul Spin technology and the exciting role of AI in lubrication for enhanced performance and longevity. Say goodbye to messy oils and hello to efficient, sustainable lubrication!