Industrial Gantry Robot | Custom Cartesian Solutions

- Home

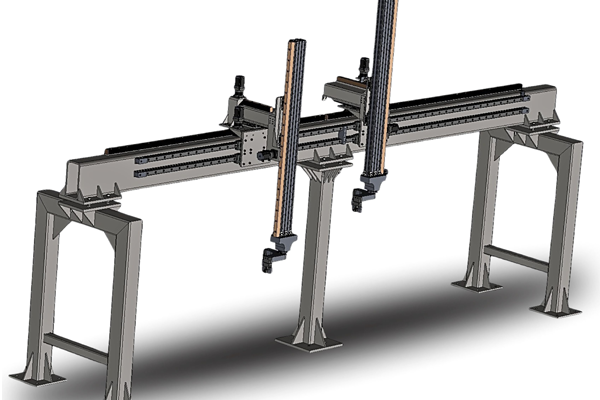

- Gantry Robot and gripper for machining center

Category

Special Purpose Robot Design Service

Project Type

Customized Design

Product/ Service Details

A Production-Assist Robotic System by Hardai ARMND Engineering Solutions.

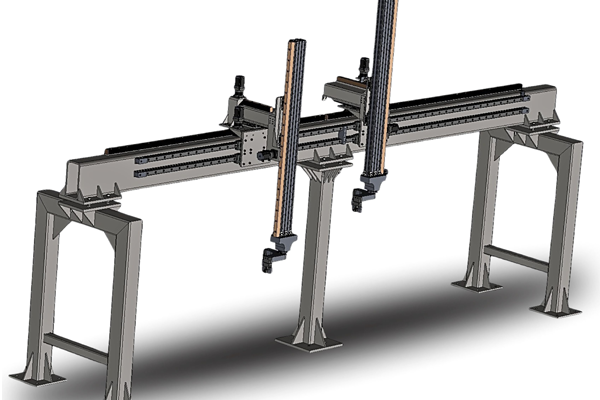

The Gantry Robot with Gripper is an advanced Cartesian Coordinate Robotic System developed by Hardai ARMND Engineering Solutions for industrial automation in the automotive manufacturing sector. The robot is engineered to perform high-speed material handling and component transfer across two grinding machining stations, optimizing productivity and precision in motorcycle drum brake production.

- System Configuration

- Design and Functionality

- Operational Role

- Key Features

- Applications

- Project Readiness

- Type: Cartesian Coordinate Gantry Robot

- Span Length: 7 meters across dual machining stations

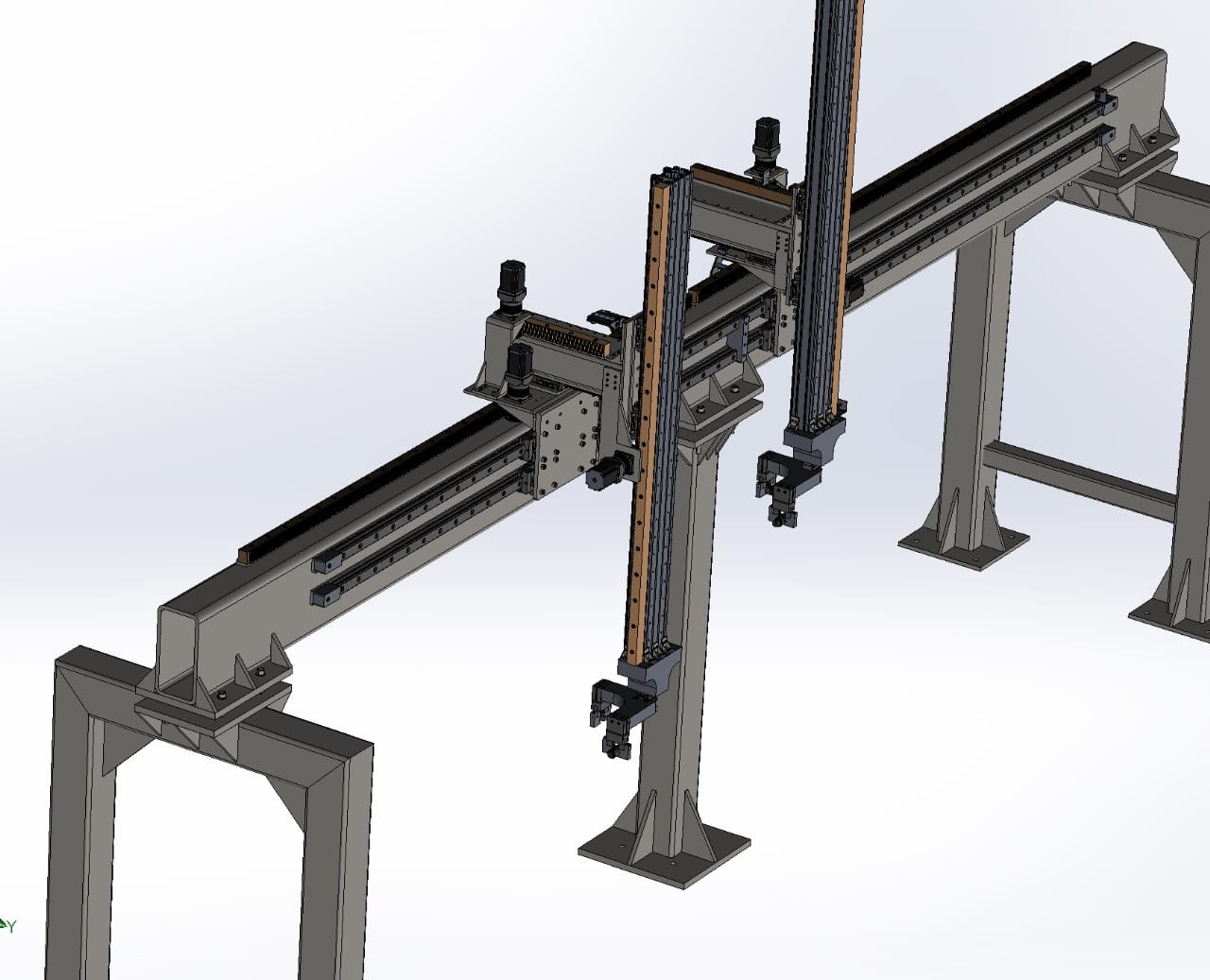

- Degrees of Freedom: 5 (X, Y, Z, Swing, and Grip)

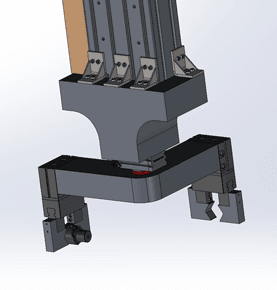

- Gripper Type: Pneumatic-actuated with self-centering jaws

- Payload: Designed to handle multiple automotive drum brake components simultaneously

- Cycle Time: Capable of handling 4 drum brakes per minute

The gantry robot is built with a rigid and precisely aligned mechanical structure, ensuring stable motion along all three linear axes (X, Y, Z). Its design allows smooth traversal and accurate positioning during the component pick-and-place process.

The integrated pneumatic gripper provides reliable and secure holding through self-centering jaws, which automatically align the drum brake cylinders for consistent and repeatable positioning. The swing motion adds additional flexibility for loading and unloading operations between two grinding stations without manual intervention.

This robot is designed to productionize and automate the grinding operation of automotive bike drum brakes. By continuously transferring components between machining centers, it enables a seamless, uninterrupted workflow, minimizing downtime and human dependency.

Operating with a continuous duty cycle, the system functions as a production-assisting robotic solution, ensuring faster cycle times, enhanced throughput, and improved product uniformity for the automotive manufacturer.

- Fully automated handling system for high-volume production lines

- Precision alignment ensuring consistent machining accuracy

- Robust Cartesian structure for long-span operations (7 meters)

- 5-axis motion enabling flexibility and reach across multiple workstations

- Pneumatic self-centering gripper for stable and accurate gripping

- Continuous duty operation supporting round-the-clock industrial usage

The Gantry Robot with Gripper is versatile and can be adapted for a range of industrial automation tasks, including:

- Automotive Component Manufacturing: Handling, loading, and unloading of drum brakes, rotors, or housings across machining centers.

- Grinding and Machining Lines: Automated transfer between grinding, milling, and finishing stations.

- Material Handling in Production Lines: Streamlining repetitive operations to improve speed and reduce human fatigue.

- Assembly Line Automation: Pre- or post-processing handling in robotic assembly environments.

- Metal Component Finishing Systems: Assisting in deburring, polishing, and cleaning processes where high precision is required.

The design of the Gantry Robot has been fully validated for manufacturing readiness. All mechanical, pneumatic, and control systems are well aligned and optimized for production build, ensuring reliability and scalability for industrial deployment.

This system reflects Hardai ARMND Engineering Solutions’ commitment to driving automation excellence in Indian manufacturing, supporting the “Made in India” initiative with indigenous robotic innovation.