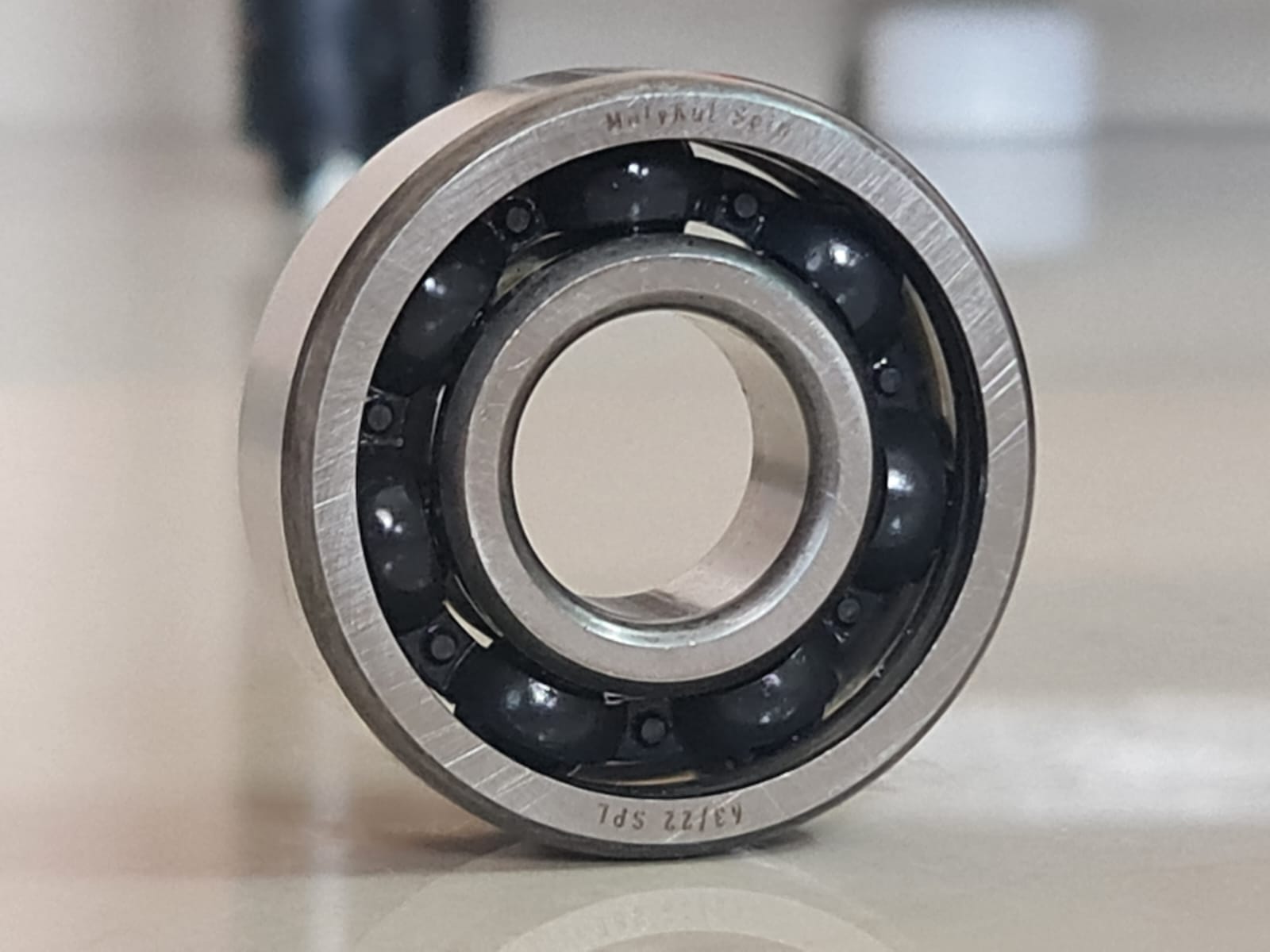

Dry Lubricant MoS2 Coated Bearings for Extreme Temperature

- Home

- MoS2 Coated Bearings

Category

Dry Film Lubrication coating on fasteners

Project Type

Monthly Production

Product/ Service Details

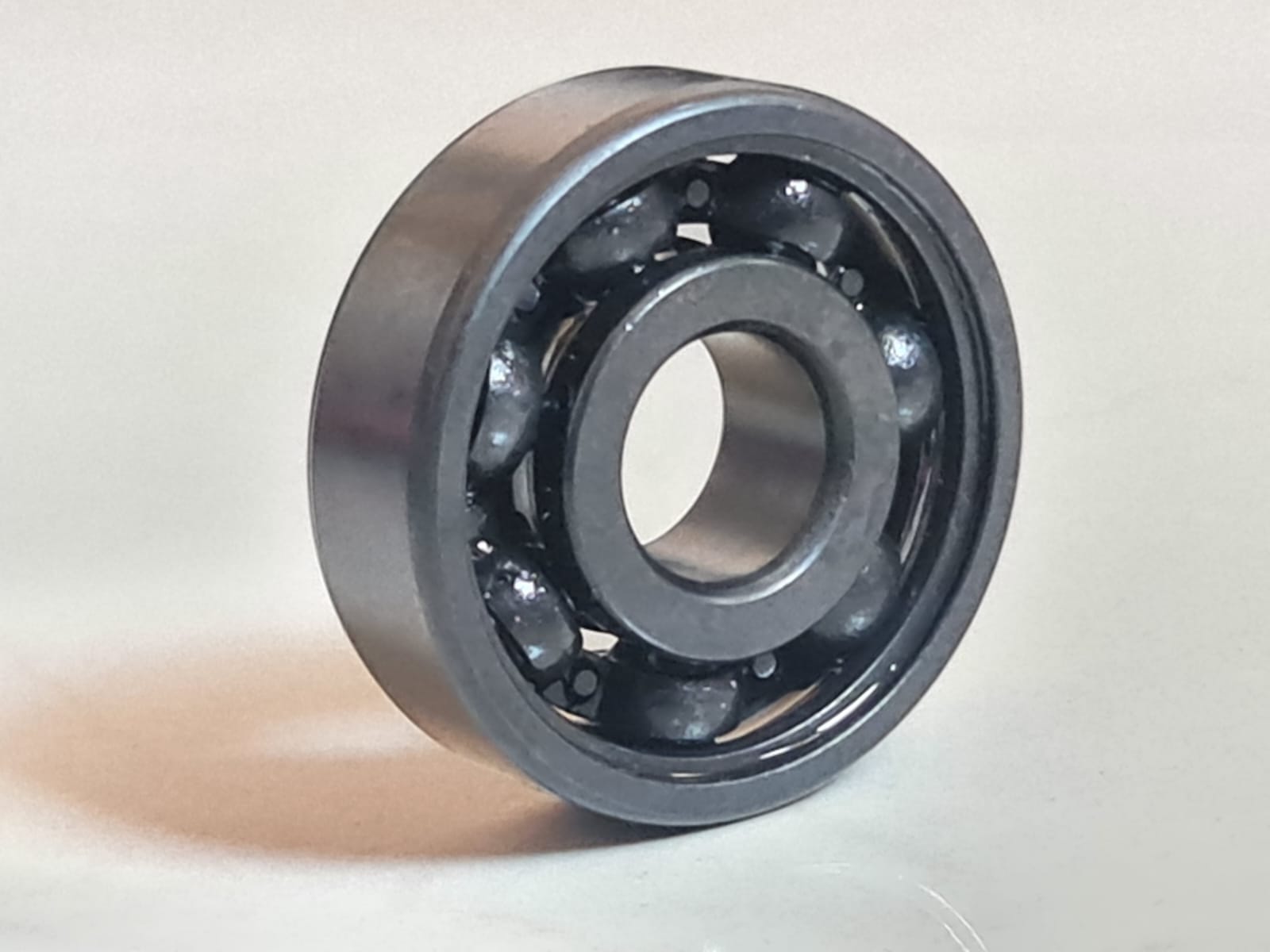

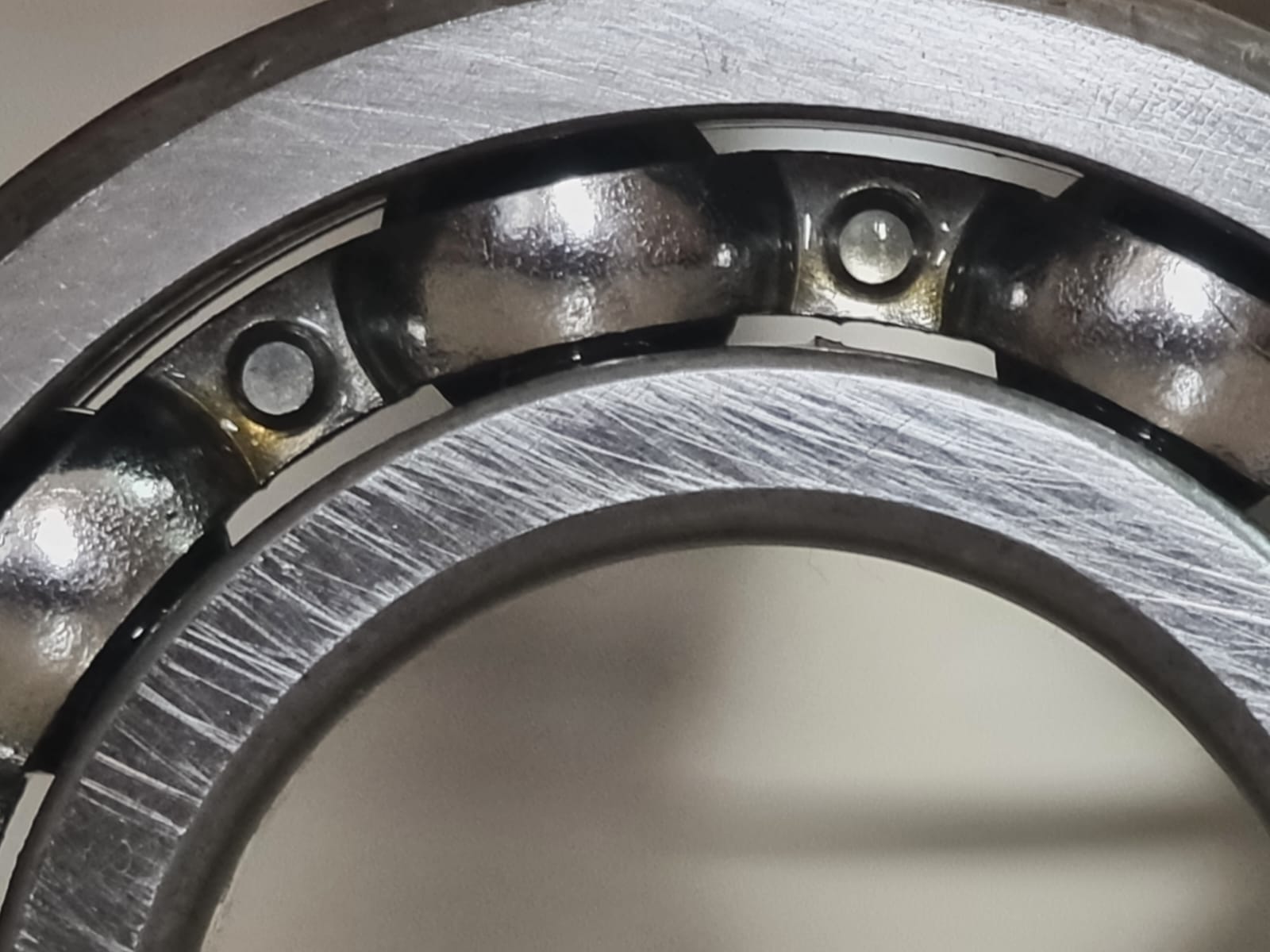

Zero-Seizure Performance: MoS2 Coated Bearings for Extreme Reliability

In mechanical engineering, the bearing is the foundation of motion. However, even the most advanced bearings face a common enemy: frictional seizure. Traditional lubrication methods often fail under stress, leading to catastrophic equipment breakdown.

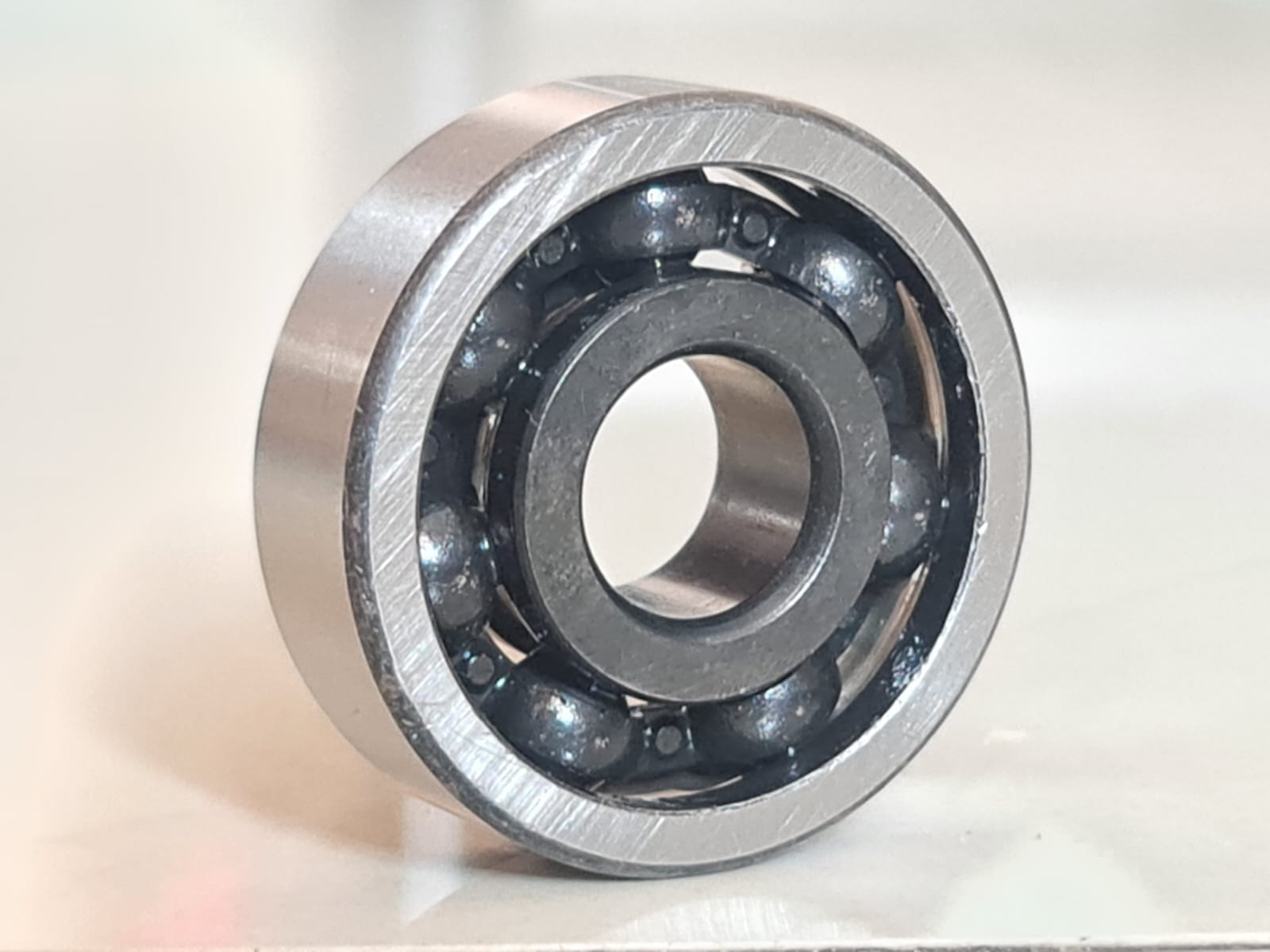

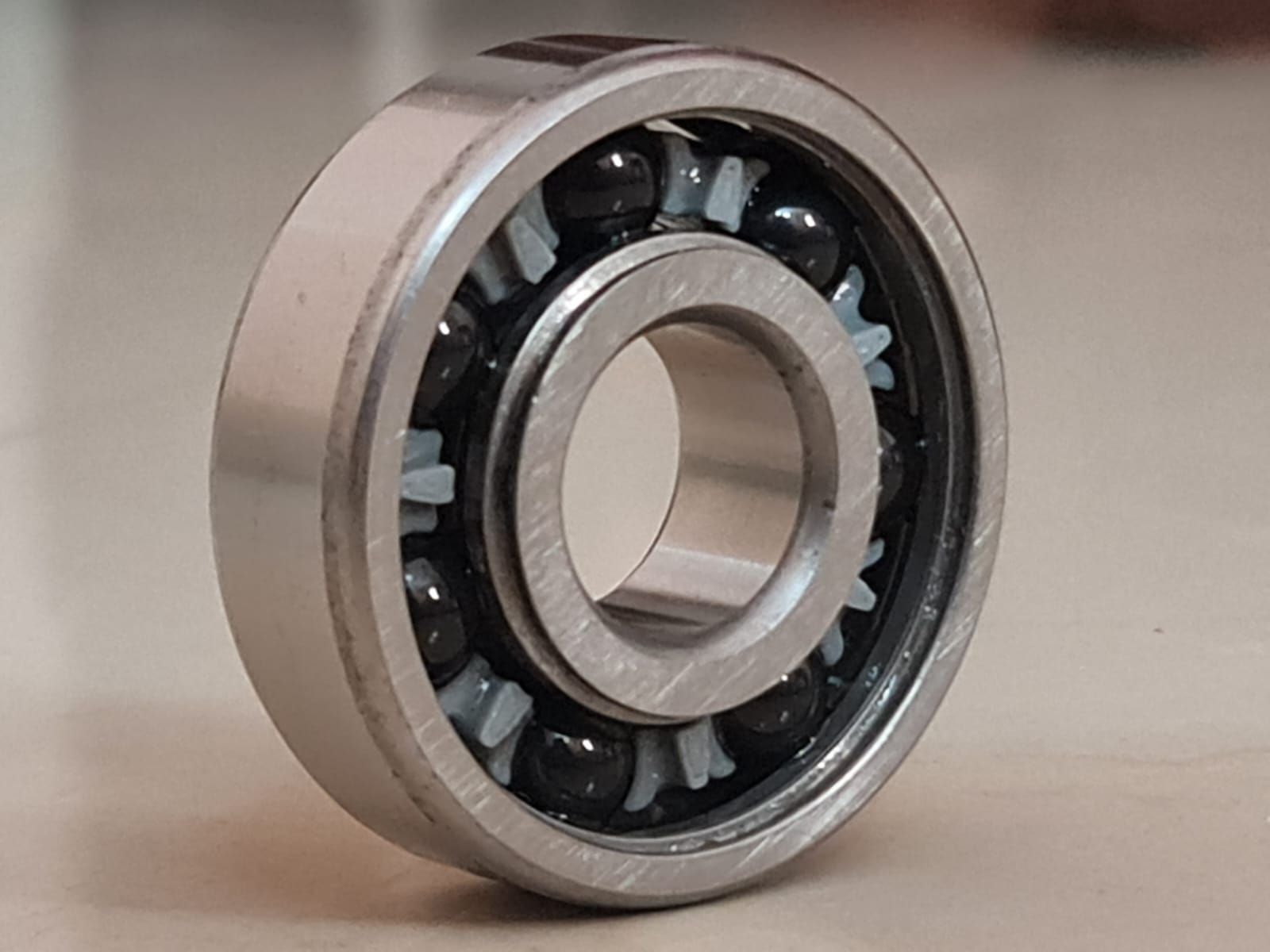

Hardai ARMND Engineering Solutions offers a permanent solution through mass-production Molybdenum Disulfide (MoS2) coating for bearing rings and rolling elements. This advanced surface treatment transforms standard bearings into anti-seize, high-performance components capable of surviving where grease and oil fail.

- The Problem

- The Solution

- Applications

- Why Choose Us

The Failure of Fluid Lubrication

Regardless of the quality, liquid oils and greases face inherent physical limitations that lead to bearing failure:

- Lubricant Erosion & Displacement: Under heavy loads, grease and oil can be squeezed out from the contact zone between the rolling element and the race. This leads to direct metal-to-metal contact.

- Frictional Overheating: Once the lubrication film breaks, friction generates rapid heat. This causes the metal components to expand thermally, reducing internal clearances until the bearing locks or "seizes."

- Contamination & Degradation: Over time, grease attracts dust and metal particles, turning into an abrasive paste. In other scenarios, ambient temperatures cause oil to evaporate (in heat) or freeze (in cold), leaving the bearing unprotected.

- The "Dry Start" Risk: During the initial seconds of rotation, oil may not have reached the critical surfaces, causing micro-wear that accumulates over time.

MoS2 as an "Infinite" Lubrication Layer

MoS2 coating creates a molecularly bonded solid lubricant film that acts as a fail-safe shield. Unlike grease, which is a separate medium, our coating becomes a part of the bearing's surface.

- Permanent Anti-Seize Protection: The MoS2 layer provides an "infinite" barrier between the rolling elements (balls or rollers) and the steady rings. Because this dry film cannot be squeezed out or eroded like liquid oil, it prevents the initial friction that leads to heat-induced expansion and seizure.

- Stability in Extreme Ambients: Our solid lubricant does not evaporate in high-heat industrial furnaces nor does it freeze in cryogenic or high-altitude aerospace applications. It remains intact and functional in environments where traditional grease would simply vanish or solidify.

- Redundant Lubrication System: While MoS2 works excellently as a standalone lubricant, it also serves as a perfect partner to oil and grease. If the primary liquid lubricant is disturbed or contaminated, the MoS_2 layer stays behind to prevent surface damage, acting as a critical safety net for the machinery.

Versatile Applications for Mass Production

Hardai ARMND Engineering Solutions operates a high-capacity facility capable of handling mass-production requirements for bearing balls, rollers, and rings across a vast range of sectors:

- Automotive & EVs: Reducing friction in wheel hubs and motor bearings to increase efficiency.

- Aerospace & Defense: Essential for satellite mechanisms, missile guidance systems, and armor tank drivetrains where reliability is non-negotiable.

- Textile & Industrial: High-speed spindles and heavy-duty industrial motors that run 24/7.

- Marine & Subsea: Providing corrosion-resistant lubrication that doesn't wash away in saltwater environments.

- Ammunition & Weaponry: Ensuring smooth operation of high-cadence firing mechanisms and rotating turrets.

Why Choose Hardai ARMND for Bearing Coatings?

Our specialized coating process ensures that the internal clearances of the bearing are maintained with micron-level precision. We provide a tenacious, low-friction finish that significantly lowers the operating temperature of the bearing, doubling or even tripling its service life compared to uncoated counterparts.

By integrating our MoS2 mass-production solution, manufacturers can guarantee Zero-Seizure performance to their end-users, even in the most unforgiving operational conditions.