MoS2 in Automation: Benefits, Uses & Performance

- Home

- MoS2 in Automation – Dry film Lubrication

Category

Dry Film Lubrication Coating on Automation Component

Project Type

Monthly Production

Product/ Service Details

Precision Performance: MoS2 Dry Film Lubrication for Automation Systems

In the era of Industry 4.0, automation systems are the backbone of high-speed manufacturing. These systems are defined by their ability to perform the same task with microscopic precision, millions of times over. Hardai ARMND Engineering Solutions specializes in Molybdenum Disulfide (MoS2) dry film lubrication, providing a critical surface treatment that ensures the repeatability, accuracy, and longevity of automated machinery.

By eliminating the variables of traditional fluid lubrication, our MoS2 coating allows robots and automated lines to maintain their exact "posture" and "position" without drift or degradation.

- The Challenge:

- The Solution

- Total System Protection

- Why Choose Us

Repeatability vs. Fluid Dynamics

Automation systems require high levels of "Repeatability"—the ability of a machine to return to the exact same coordinates every single time. Traditional lubrication often hinders this goal:

- Viscosity Fluctuations: As a factory heats up throughout the day, grease and oil become thinner. This change in "drag" or resistance can cause minute timing shifts and positional errors in high-speed movements.

- The "Stick-Slip" Phenomenon: When a robotic arm stops and starts, it must overcome "stiction." If the lubricant film is inconsistent, the arm may "jump" slightly at the start of a movement, ruining the precision of delicate tasks like PCB assembly or laser welding.

- TMaintenance Downtime: Frequent re-greasing of ball screws and LM guides leads to planned downtime, which is the enemy of a fully automated, 24/7 production environment.

MoS2 Coating for Infinite Precision

The MoS2 coating applied by Hardai ARMND Engineering acts as a permanent, solid-state lubricant. It does not flow, evaporate, or change with temperature, providing a constant friction value that is essential for automation.

- Enhanced Positional Repeatability: Because MoS2 provides a consistent coefficient of friction regardless of speed or temperature, the control system of the automation unit can be tuned with absolute certainty. The "resistance" remains the same in the morning as it does at night, ensuring the machine hits the same position and posture in every cycle.

- Elimination of Stiction for Precise Posturing MoS2 has an incredibly low static-to-kinetic friction ratio. This eliminates "stick-slip" behavior, allowing for smooth, fluid motion even at the microscopic level. This is vital for high-precision rocker arms and pins that must hold specific angles without vibrating or shifting.

- Long-Term Reliability of Motion Components Our coating protects the "heavy lifters" of the automation system:

- Ball Screws & LM Guides: Ensures smooth linear travel with zero backlash and no dependence on grease film formation.

- Gears & Bearings: Provides a secondary layer of protection that prevents wear-induced "play" or looseness in the system.

- Rocker Arms & Rocker Pins: Maintains the integrity of the pivot points, ensuring the mechanical "posture" of the system remains rigid and accurate over years of service.

Hardai ARMND Engineering

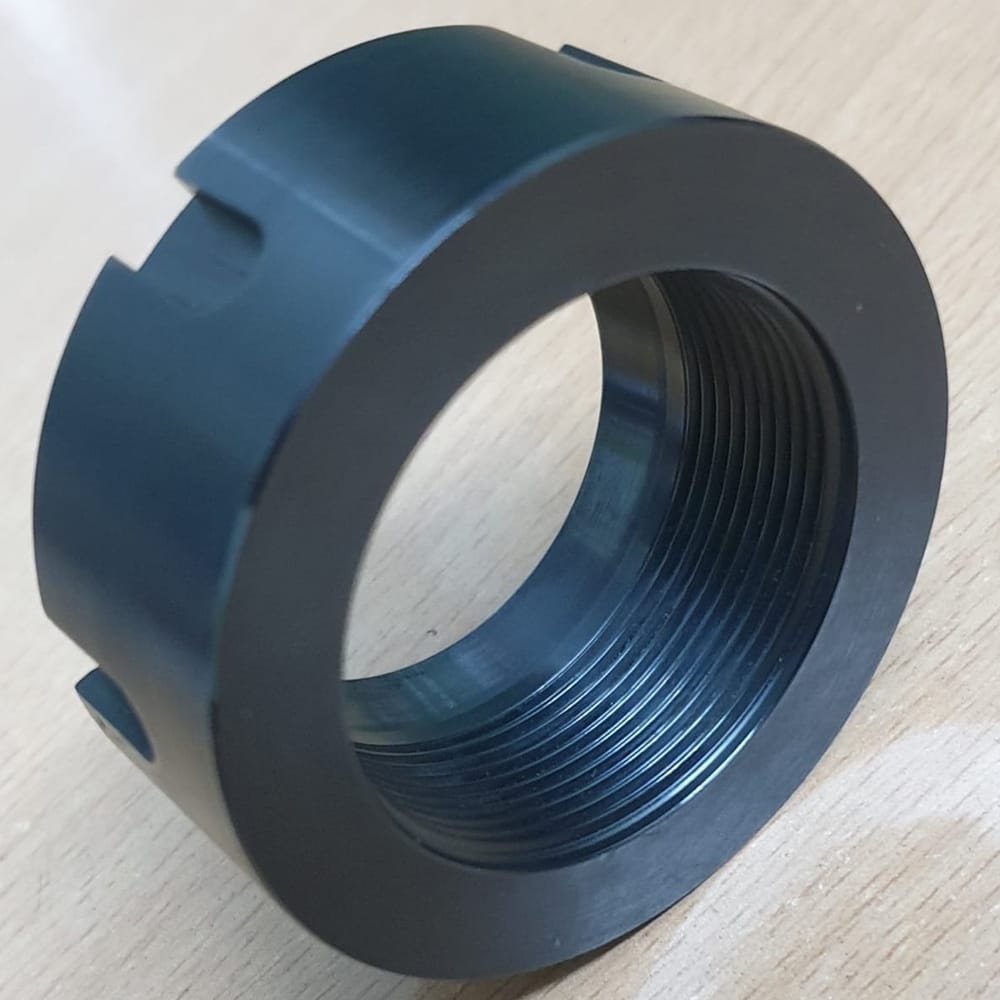

We provide mass-production MoS2 coating solutions for a comprehensive list of automation components, ensuring the entire kinematic chain is protected:

- Actuators & Rocker Arms: For smooth, repeatable angular movements.

- Linear Motion (LM) Guides: To ensure perfectly straight, low-friction travel.

- Fasteners & Circlips: Preventing micro-vibration loosening and ensuring structural stability.

- Spacers & Washers: Maintaining exact clearances within the assembly to prevent mechanical drift.

Why Choose Hardai ARMND for Automation?

| Feature | Benefit for Automation |

|---|---|

| Consistent Friction | Guarantees repeatable positional accuracy. |

| Zero Maintenance | Reduces the need for manual grease intervals. |

| Temperature Stable | No change in machine "feel" or timing due to factory heat. |

| Clean Operation | No oil mist or grease leakage, ideal for clean-room automation. |

Hardai ARMND Engineering Solutions is your partner in achieving the highest OEE (Overall Equipment Effectiveness). By treating your automation components with MoS2, you are investing in a system that moves with the same precision on its millionth cycle as it did on its first.