Performance of MoS2 Coated Steel Balls | Industrial Guide

- Home

- MoS2 Coated Steel Balls and Roller

Category

Dry Film Lubrication Coating on Steel Balls

Project Type

Monthly Production

Product/ Service Details

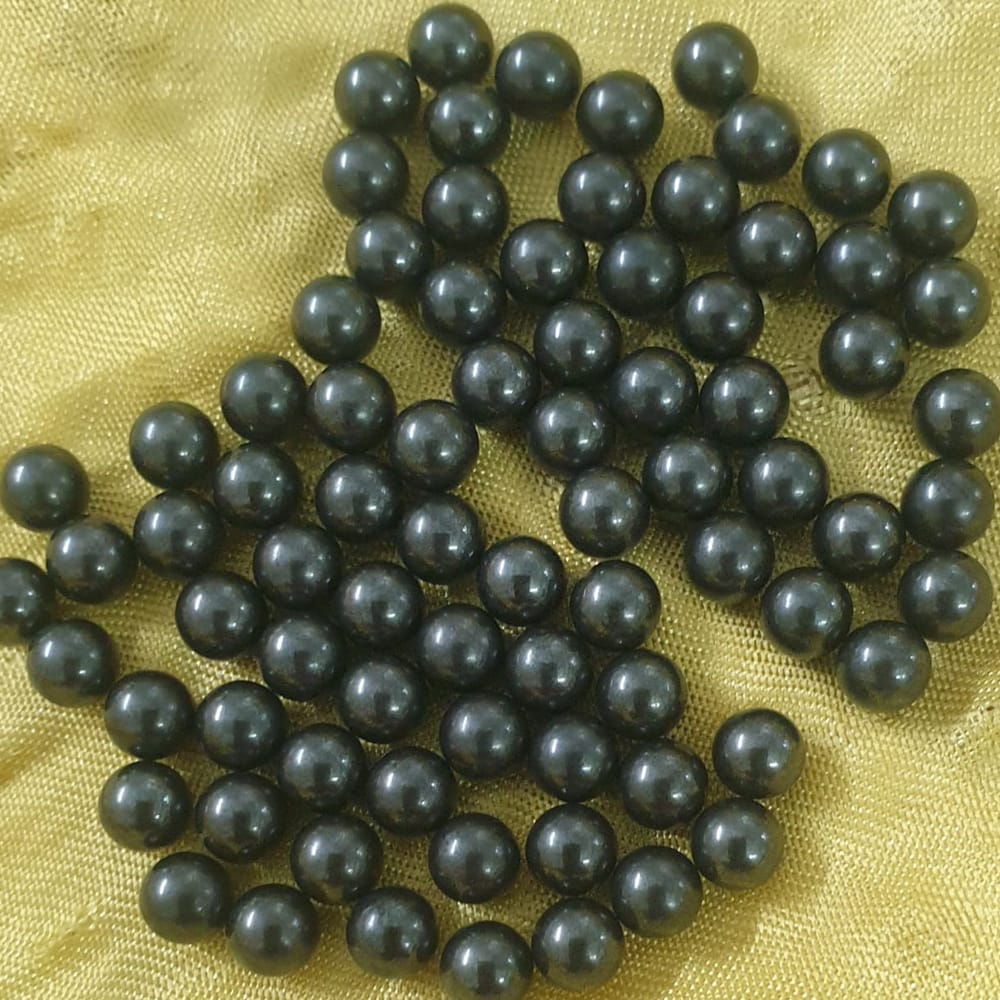

Micro-Motion Mastery: MoS2 Coating for Steel Precision Balls

In the world of high-precision engineering, the most difficult challenge isn’t high-speed rotation—it’s micro-motion. Hardai ARMND Engineering Solutions has developed a specialized project for the mass-production of Molybdenum Disulfide (MoS2) coated steel balls. This project addresses the critical failure of liquid lubricants in applications involving short strokes, oscillating movements, and static-to-motion transitions.

By transforming a standard steel ball into a self-lubricating spherical component, we provide the "instant" lubrication required for the world’s most sensitive machinery.

- The Challenge

- The Solution

- Applications

- Why Choose Us ?

The Failure of "Dynamic" Lubrication

Most mechanical systems rely on grease or oil, which operate on the principle of hydrodynamic lubrication. This means the lubricant only forms a protective film when there is enough speed to "pump" the fluid between the metal surfaces.

- The Micro-Movement Problem: In applications like LM Guides, Linear Bearings, and Ball Screws, the balls often move in very short distances or at slow speeds. This motion is insufficient to pull a layer of grease into the contact zone.

- The "Stick-Slip" Effect: Without a pre-existing film, the ball experiences high static friction. This causes jerky, inconsistent movements (stiction), which is fatal for precision in Optical Aperture Machines or medical equipment.

- Boundary Conditions: In spherical joints and thrust bearings that undergo frequent start-stop cycles, the oil film collapses every time the motion stops, leading to metal-to-metal grinding upon the next movement.

Pre-Existing "Infinite" Micro-Film Lubrication

The MoS2 coating process by Hardai ARMND Engineering eliminates the need for "motion assistance" to create a lubricant film. The coating is a solid, dry film that is already present on the surface of the steel ball before the machine even starts.

- Instantaneous Lubrication (Zero-Lead Time): Because the MoS2 is molecularly bonded to the steel ball, there is an "infinite" lubricating film present at the contact point. Whether the ball moves one millimeter or one kilometer, the lubrication is immediate. This is critical for Linear Motion (LM) Guides where precision positioning is required without the delay of oil film formation.

- Perfect for Spherical Joints and Oscillations: In spherical joints that only tilt or rotate by a few degrees, grease often gets pushed to the sides and stays there. Our MoS2 coating remains on the "load zone" of the ball, providing constant protection against wear and ensuring smooth, fluid movement in every direction.

- Low Coefficient of Friction for Optical Precision: For Optical Aperture Machines and high-end sensors, even the slight resistance of thick grease can throw off measurements. MoS2 provides a dry, ultra-low friction surface that ensures microscopic accuracy without the "drag" or "churning" resistance of traditional lubricants.

Versatile Applications of Coated Steel Balls

Hardai ARMND Engineering Solutions provides mass-production coating for steel balls used in:

- Linear Motion Systems: LM Guides and Linear Bearings requiring high positional accuracy.

- Ball Screws: Ensuring smooth power transmission with zero backlash and no "stiction."

- Thrust & Radial Bearings: Protecting against "false brinelling" (vibration-induced wear) during transport or idle periods.

- Spherical Joints: Facilitating smooth multi-axis rotation in robotics and automotive suspensions.

- Precision Instruments: Optical apertures, measuring gauges, and laboratory equipment.

Hardai ARMND Mass Production

Our facility utilizes specialized tumbling and batch-coating technologies to ensure that every single steel ball—regardless of size—receives a 100% uniform coating thickness. This is vital for maintaining the spherical tolerance and grade of the ball.

- Dimensional Integrity: Our process adds only a few microns of thickness, ensuring the balls still fit perfectly within their high-tolerance races.

- Extreme Load Bearing: The MoS2 film can withstand pressures that would normally rupture a liquid oil film.

- Dry & Clean: Perfect for vacuum or clean-room environments where oil vapors could contaminate sensitive optical or electronic parts.