MolyKul Mono-Coat – High-Performance Industrial Coating

- Home

- MolyKul Mono-Coat

MolyKul Mono – Coat

- Best cost and quality as sophisticated

- Made In India Self proprietary synthesis

- The only mass production commitment in the world

MolyKul Mono-Coat, a MoS2 Dry film lubrication product by Hardai ARMND has emerged with numerous possibilities to enhance motion properties of machine mechanisms. A Nano lubrication technology, Made In India.

- Reducing friction and wear through its low-friction interface

- Enhancing efficiency by minimizing metal-to-metal contact

- Providing lubrication and corrosion resistance

- Extending component life and reducing maintenance costs

- Offering versatility for high-load, high-speed, and harsh environments

- Improving performance in bearings, LM guides, pumps, and other applications

DFL Coating by HAES

- MoS2 Coating for textile machine component: MoS2 coating on metal ring traveller to completely eleminating present practive of oil lubrication, is revolutionary method to improve yarn quality, reduce production cost, reduce downtime and maintanence. Join us on Linkedin

- MoS2 Coating on manufacturing machine components: The problem of jamming the collet, chuck and other moving marts of CNC machine and other manufacturing machine is a common problem. While maintanence, these components may breakdown. Presently, industrialists uses temperory solution of appying general purpose grease or costly grease to these components. MoS2 Dry lubrication coating is the permanant solution to manufacturing industry. Contact us for more info

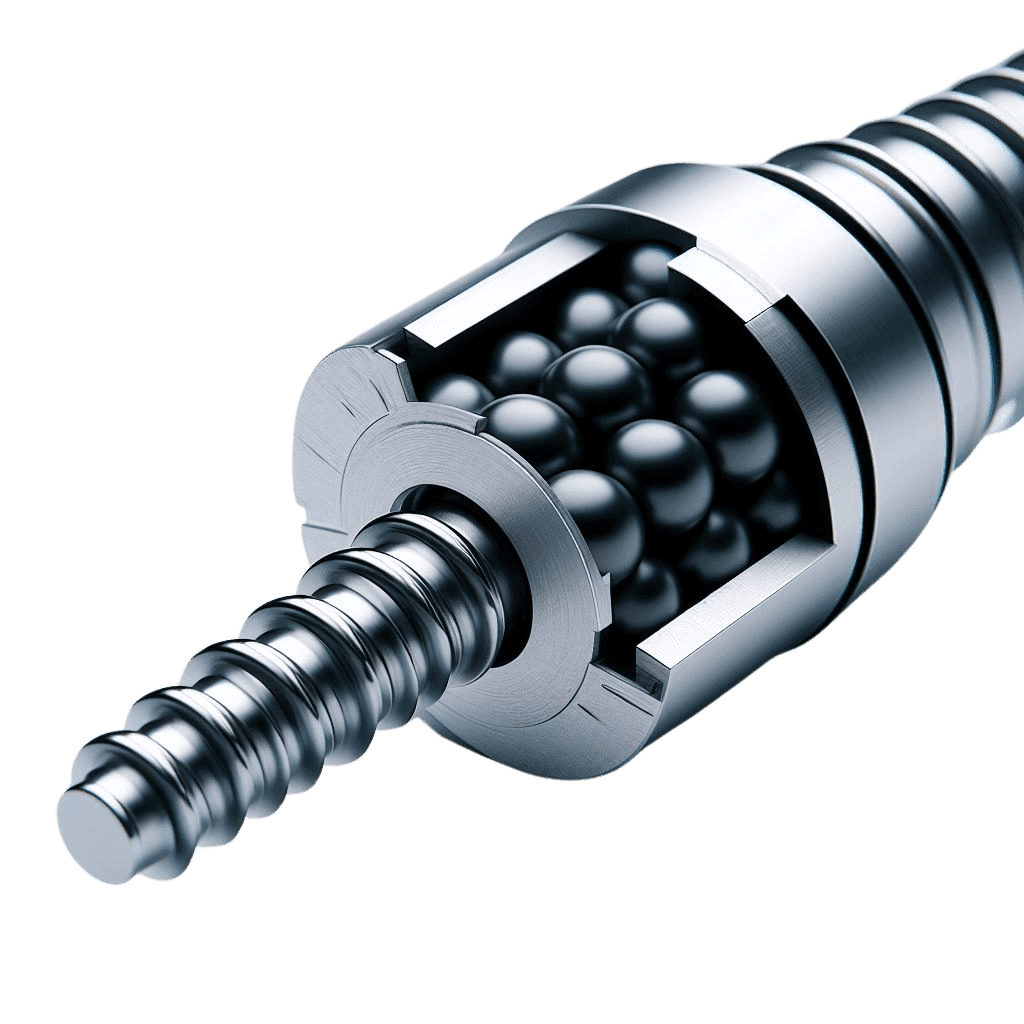

- MoS2 Coating on automation components: Automation components like ball scew nuts, LM guide blocks, bearing components, bearing balls, steel balls, fasteners, circlips and washers, waved washers, nut and bolts, can be coated with MoS2 for improving life and efficiency. MoS2 coating brings up the reliability of these components in extreme and precision applications like aerospace and manufacturing. Contact us for more info

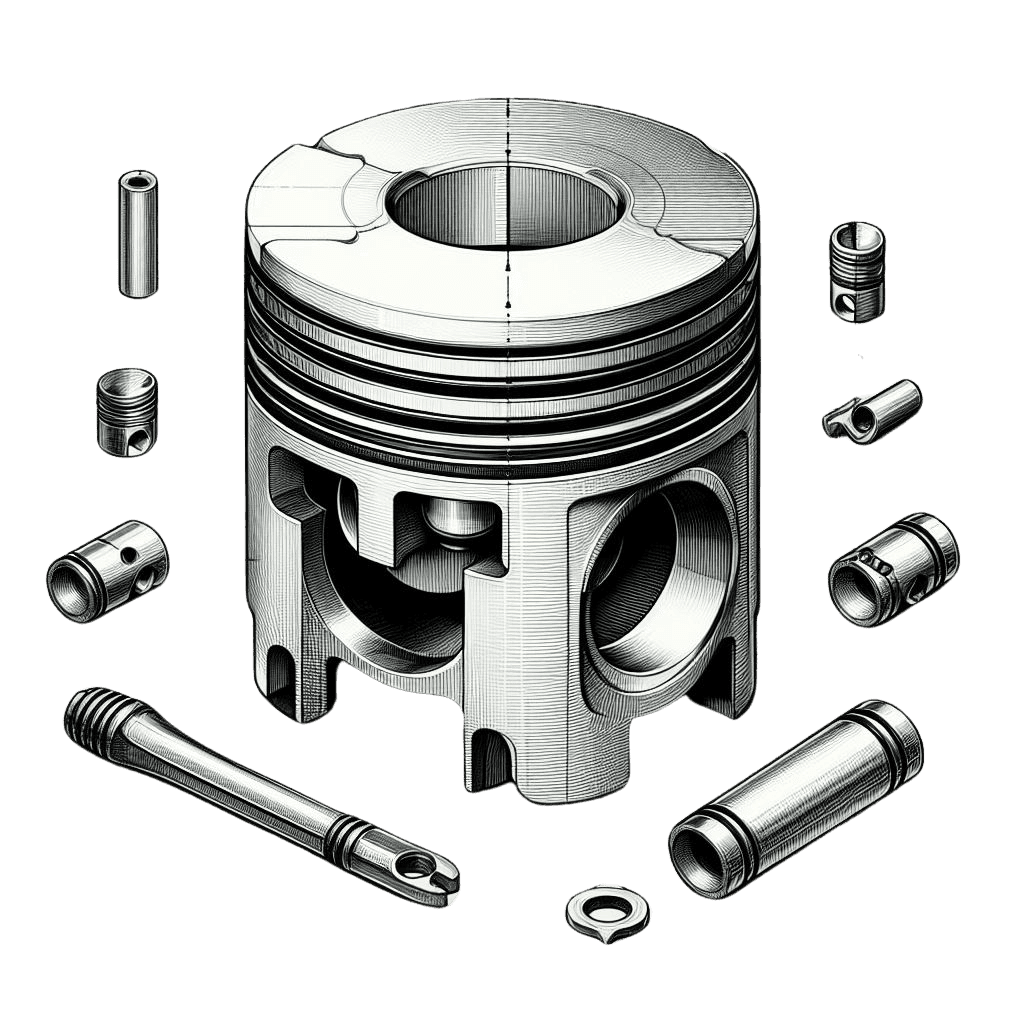

- MoS2 Coating on Engine & transmission components: Engine piston rings, cam shafts, springs, bearings and gears often wears out in engines due to rough use of it. Regular maintanence is not often observed by the user and the engine gets breakdown soon due to thermal loads and frictional loads. MoS2 coating on these components reduces the chances of breakdown due to thermal and frictional loads on these components. Contact us for more info

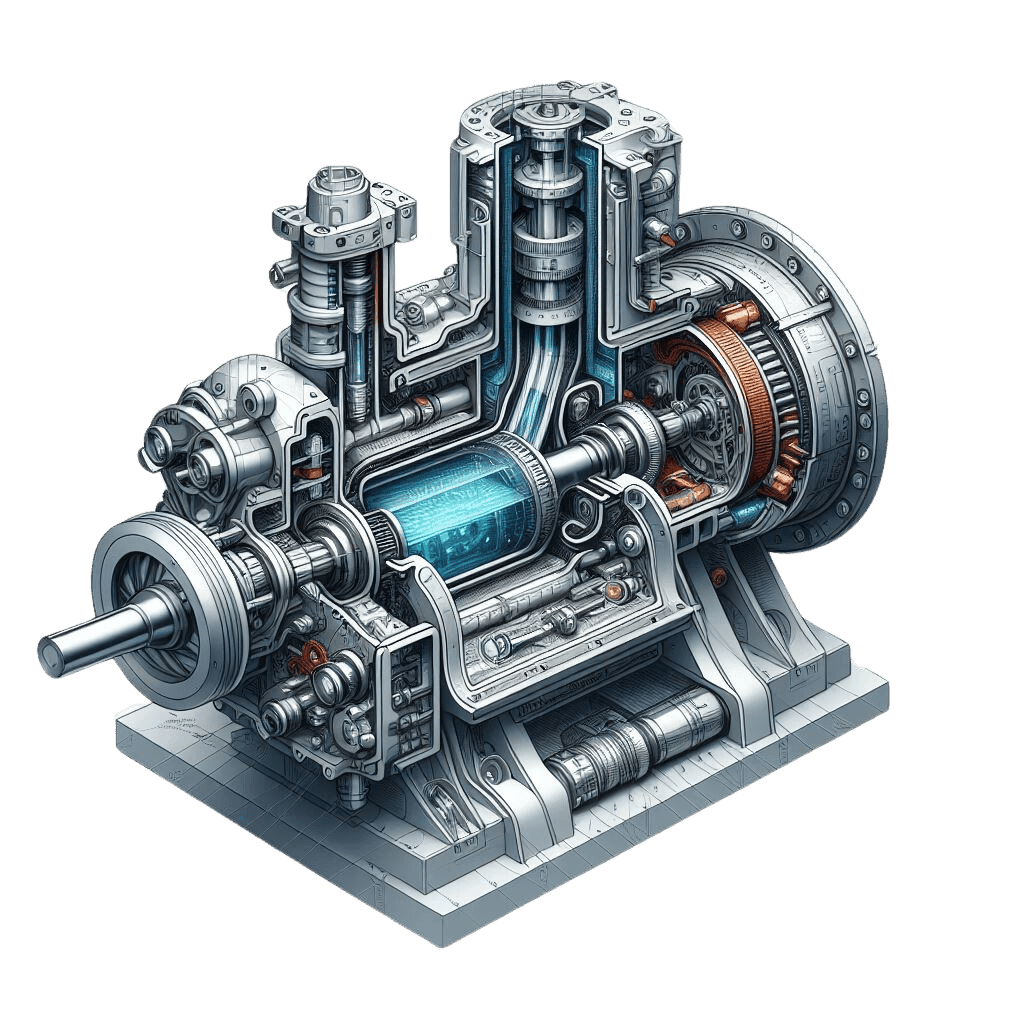

- MoS2 Coating on pumps and compressors components: Due to harsh environments like hard water, chemicals, oils, contaminated fuids, acids and salt liquids and moisturous air, components of pumps and compressors like bearings, swash pates, scews and threaded parts, seals, covers and fans, turbines and piston components often fails to serve the best efficiency. MoS2 coating not only is dry lubrication coating but also, protect components against corrosion. Contact us for more info

- MoS2 Coating on turbochargers components: Trurbochargers are high speed rotating components experinces heat and mist frictions. Due to which, the bush bearings, spacers and washers maintaining the precision and efficiency wears out and turbochargers looses its efficiency. MoS2 on bush bearings and MoS2 coating on spacers and washers of turbochargers, dry lubricate them locally even at extreme conditions and provides long term efficiency output by the turbocharger. Contact us for more info

| MoS2 dry film lubricant Coating Specifications | Parameters |

|---|---|

| Film Material | Molybdenum Di sulfide (MoS2) |

| Coating on of ball bearing diameter | 1mm to 35mm |

| Colour | Black |

| Customized doping as per application | Copper, Tin, Titanium, Chromium, Silicon, SiO2 and 16 other combinations of alloys as per application |

| Film thickness | 1μm to 8μm |

| Minimum Particle Size | 10 nanometer |

| Coefficient of friction (COF) | Tested as per ASTM G99 (Pin in disc test) with different compounding |

| 35000 RPM for 4 Hours (No Oil and No Grease) | 35000 RPM for 4 Hours (No Oil and No grease) |

Rotating Machines

Cylindircal Roller Bearing

Applications where MoS2 coating is benificial on cylindrical roller bearings

- Wheel hubs in vehicles

- Conveyor systems in industrial settings

- Crushers in mining operations

- Turbines in power generation

- Locomotives in rail transportation

- Tractors in agricultural machinery

- Aircraft engines in aerospace industry

- Ship propulsion systems in marine industry

- Forklifts in material handling equipment

- Filling machines in food and beverage processing

- MRI machines in medical equipment

- Robotic arms in robotics

- Yaw systems in wind turbines

- Pumps in petrochemical industry

- Printing presses in printing industry

- Spinning machines in textile industry

- Rolling mills in steel mills

- Labeling machines in packaging machinery

- Elevators in elevators and escalators

- Cranes in earthmoving equipment

Tappered Roller Bearing

Applications where MoS2 coating is benificial on Tappered roller bearings

- Gearboxes in industrial machinery

- Spindle assemblies in machine tools

- Aircraft landing gear

- Wind turbine gearboxes

- Marine propulsion systems

- Printing press cylinders

- Power take-off (PTO) units in tractors

- Rock crushers

- Traction motors in locomotives

- Forklift mast assemblies

- Paper mill rollers

- Differential assemblies in automobiles

- Hydraulic pumps

- Electric motor shafts

- Axle shafts in off-road vehicles

- Roller coaster drive systems

- Bicycle cranksets

- Trailer axles

- Water pumps in irrigation systems

- Crankshafts in engines

Deep groove ball bearing

Applications where MoS2 coating is benificial on Deep groove ball bearings

- Conveyor belt rollers

- Washing machine drum bearings

- Water pump motors

- Electric motors

- Air conditioning compressors

- Vacuum cleaner brush rollers

- Handheld power tools

- Exercise equipment mechanisms

- Garage door opener mechanisms

- Conveyor systems

- Packaging machinery

- Material handling equipment

- Pneumatic tools

- Industrial fans

- Pumping systems

- Printing presses

- Industrial mixers

- CNC machines

- Injection molding machines

- Rotary kilns

Planetary Gear train

Applications where MoS2 coating is benificial on Planetary gear box

- Robotics arms

- Industrial mixers

- Printing presses

- Steel rolling mills

- Oil and gas drilling rigs

- Automotive assembly line robots

- Textile machinery (e.g., spinning frames)

- Packaging machinery (e.g., form-fill-seal machines)

- Marine propulsion systems

- Food processing machinery (e.g., dough mixers, extruders)

- Elevators and escalators

- Paper and pulp machinery (e.g., paper machines)

- Aerospace industry machinery (e.g., aircraft engines, landing gear systems)

- Chemical processing equipment (e.g., reactors, mixers)

- Plastic extrusion machines

- CNC machining centers

- Metal cutting and milling machines

- Hydraulic presses

- Earthmoving equipment (e.g., bulldozers, loaders)

- Industrial robots for material handling

Compound gear train

Applications where MoS2 coating is benificial on compound gear box

- Rolling mills in steel manufacturing

- Rotary presses in printing industry

- Extruders in plastic manufacturing

- Mixers in chemical processing

- Drilling rigs in oil and gas exploration

- Milling machines in metalworking

- Lathes in machining operations

- Shearing machines in metal fabrication

- Wire drawing machines in wire manufacturing

- Tube mills in tube manufacturing

- Autmotive gear box

- Cranes in material handling

- Hoists in construction and manufacturing

- Pumps in water treatment plants

- Compressors in industrial applications

- Shredders in recycling facilities

- Crushers in mining and quarrying

- Granulators in fertilizer production

- Agitators in food processing

- Dryers in manufacturing processes

Ball screw & Roller screw

Applications where MoS2 coating is benificial on Deep groove ball bearings

- CNC milling machines

- CNC lathes

- 3D printers

- Laser cutting machines

- Electric injection molding machines

- Coordinate measuring machines (CMM)

- Robotic arms

- Automated assembly machines

- Packaging machinery

- Semiconductor manufacturing equipment

- Medical imaging devices (e.g., CT scanners, MRI machines)

- Electron microscopes

- CNC routers

- Industrial automation systems

- Machine tools (e.g., grinding machines, drilling machines)

- Inspection equipment (e.g., vision systems)

- Textile machinery (e.g., knitting machines)

- Material handling equipment (e.g., gantry cranes)

- Printing presses

- Automotive manufacturing equipment (e.g., assembly line robots)

Bush Bearings

Applications where MoS2 coating is benificial on Bush bearings

- Electric motors

- Pumps (centrifugal, diaphragm, piston, etc.)

- Fans and blowers

- Compressors (reciprocating, rotary screw, etc.)

- Turbines (steam, gas, hydraulic)

- Gearboxes (helical, bevel, worm, etc.)

- Hydraulic cylinders

- Conveyors (belt, roller, screw, etc.)

- Cranes and hoists

- Machine tools (lathes, milling machines, etc.)

- Agricultural machinery (tractors, combines, etc.)

- Marine propulsion systems (ship engines, propeller shafts, etc.)

- Printing presses

- Food processing equipment (mixers, grinders, etc.)

- Mining equipment (crushers, screens, etc.)

- Textile machinery (looms, spinning frames, etc.)

- Construction equipment (excavators, bulldozers, etc.)

- Material handling equipment (forklifts, pallet jacks, etc.)

- Paper and pulp machinery (pulpers, refiners, etc.)

- Packaging machinery (filling machines, labeling machines, etc.)

Rotating shafts & Cam followers

Applications where MoS2 coating is benificial on rotating shaft and cam follower

- Miniature CNC machines

- Compact 3D printers

- Small-scale packaging machinery

- Microfluidic devices

- Precision medical devices

- Miniature robotic arms

- Small-scale automation systems

- Micro-electromechanical systems (MEMS)

- Microscopy equipment

- Portable handheld instruments

- Small-scale textile machinery (e.g., knitting machines)

- Laboratory automation equipment

- Miniature injection molding machines

- Small-scale engraving machines

- Compact assembly line robots

- Portable analytical instruments (e.g., spectrometers)

- Miniature drilling and milling machines

- Compact woodworking machinery (e.g., mini lathes)

- Precision watchmaking and clockmaking machinery

- Small-scale semiconductor manufacturing equipment

Coupling

Applications where MoS2 coating is benificial on components of coupling

- Gas turbines

- Steam turbines

- Centrifugal pumps

- Compressors (reciprocating and rotary)

- Electric motors

- Generators

- Hydraulic pumps and motors

- Cooling tower fans

- Blowers

- Paper and pulp machinery (e.g., refiners)

- Printing presses

- Conveyors

- Lathes

- Milling machines

- Automotive assembly line equipment

- Marine propulsion systems

- Crushers (mining equipment)

- HVAC fans

- Chemical reactors

- Food processing conveyors

Non-Rotating Machines

Engine Pistons and components

Applications where MoS2 coating is benificial on Pistons and engine components

- Piston Rings

- Compression Rings

- Oil Control Rings

- Wrist Pins (Piston Pins)

- Piston Skirt

- Piston Crown

- Connecting Rod

- Small End (Wrist Pin End)

- Large End (Crankshaft End)

- Crankshaft

- Main Journals

- Rod Journals

- Cylinder Liner (Sleeve)

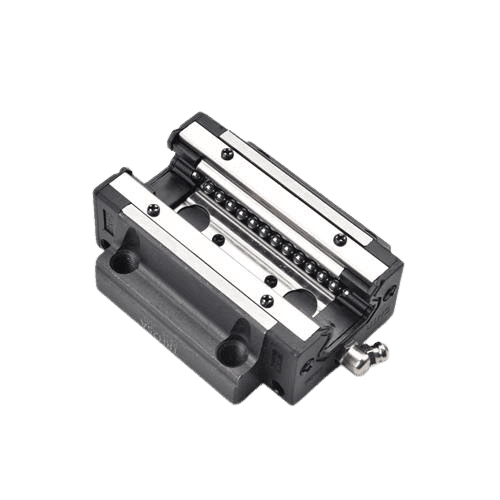

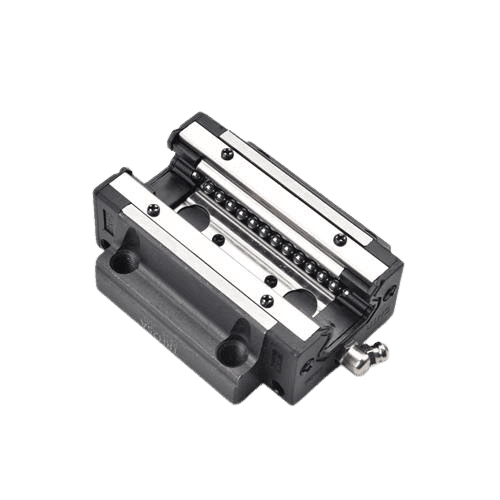

Slides and linear motion guides block

Applications where MoS2 coating is benificial on Linear motion guide block

- CNC milling machines

- CNC lathes

- Laser cutting machines

- 3D printers & diamond cutting machines

- Coordinate measuring machines (CMM)

- Industrial robots

- Automated packaging machines

- Textile machinery (e.g., weaving machines)

- Semiconductor manufacturing equipment

- Inspection equipment (e.g., vision systems)

- Material handling systems (e.g., conveyor belts)

- Pick-and-place machines

- Engraving machines

- Printing presses

- Assembly line equipment

- Wire and cable processing machines

- Automated storage and retrieval systems (AS/RS)

- Medical imaging devices (e.g., MRI machines)

- Woodworking machinery (e.g., CNC routers)

- Metal stamping and forming machines

Hydraulic cylinders

Applications where MoS2 coating is benificial on Hydraulic cylinder

- Piston rod

- Piston

- Cylinder bore

- Cylinder head

- Cylinder barrel

- Rod bearings

- Rod guide

- Cylinder end caps

- Rod clevis

- Cylinder mounting hardware

- Piston ring grooves

- Piston seals

- Rod seals

- Wear bands

- Head caps

- Threaded rod ends

- Retaining rings

- Nuts and bolts

- Lock nuts

- Tie rods

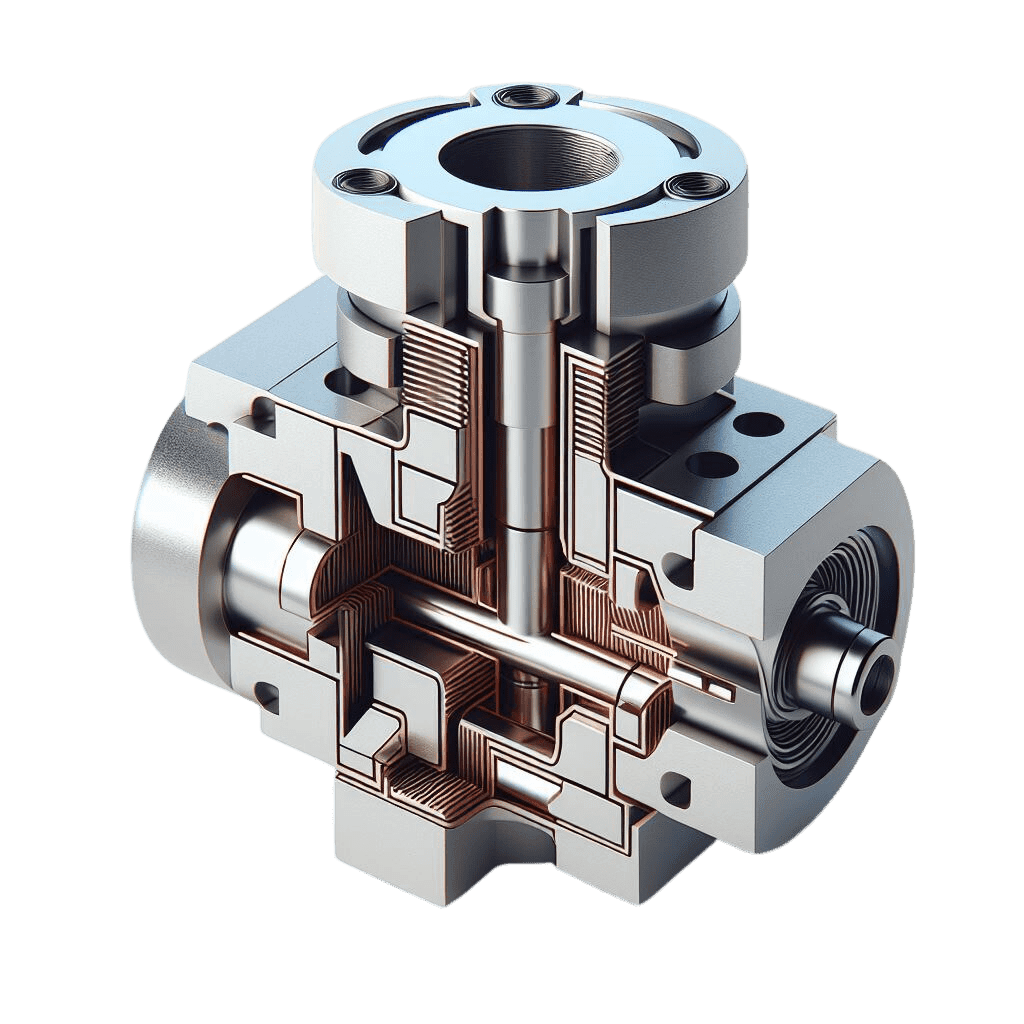

Hydraulic Valves

Applications where MoS2 coating is benificial on components of hydraulic valve

- Spools

- Valve bodies

- Actuator mechanisms

- Relief valve discs

- Seats

- Solenoid armatures

- Cartridge bodies

- Solenoid coils

- Plungers

- Pilot valves

- Poppet valves

- Springs

- Cartridge housings

- Check valve bodies

- Pressure control valve seats

- Flow control valve spools

- Proportional valve spools

- Sequence valve bodies

- Pressure reducing valve seats

- Directional control valve bodies

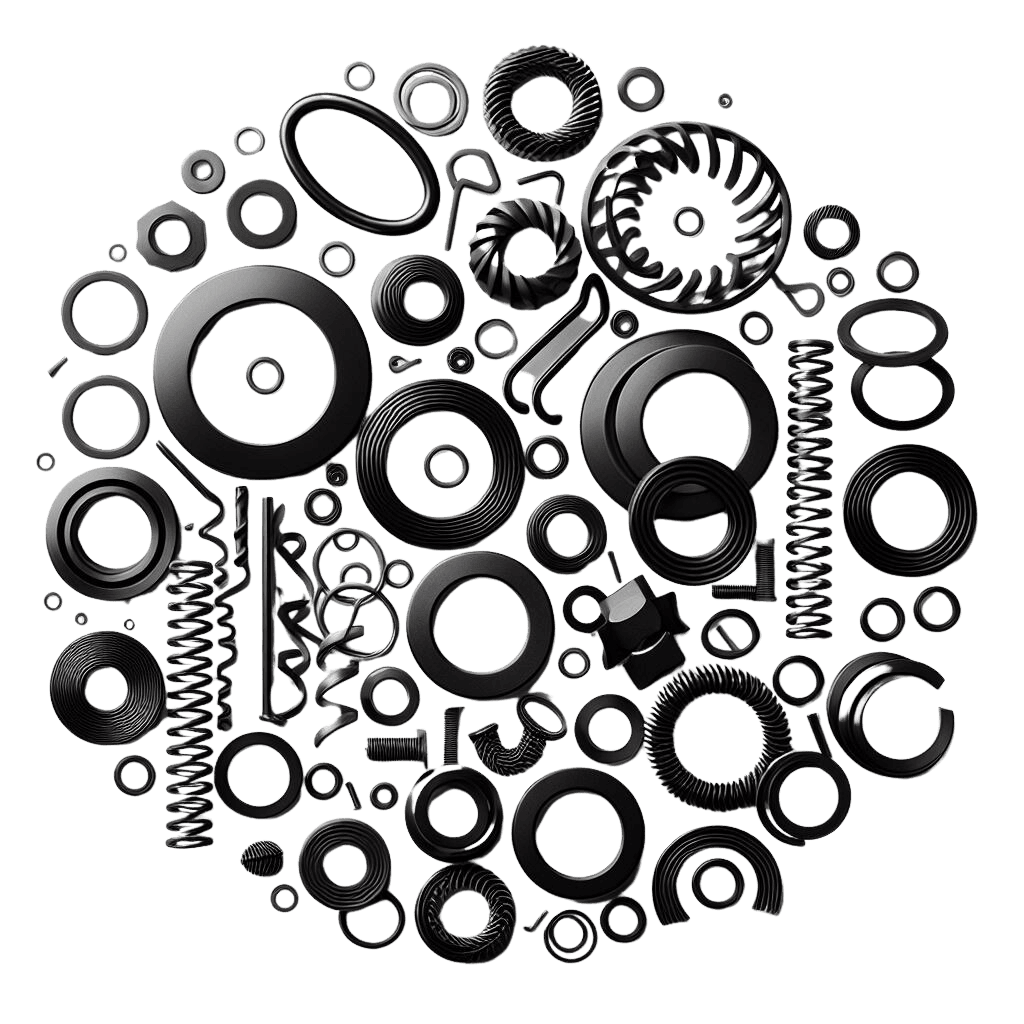

Spacers, circlips, washers and retaining ring

Applications where MoS2 coating is benificial on Spacers, washers, circlip and retaining rings

- Round spacers

- Hex spacers

- Standoff spacers

- Sleeve spacers

- Tapered spacers

- Threaded spacers

- Shoulder spacers

- Collar spacers

- Swage spacers

- Flanged spacers

- Belleville washers

- Finger spring washers

- Crescent spring washers

- Serrated spring washers

- Wave spring washers

- Compression springs

- Extension springs

- Torsion springs

- Constant force springs

- Wave springs

- Disc springs (Belleville washers)

- V-springs

- External retaining rings (circlips)

- Internal retaining rings

- E-clips

- Snap rings

- Spiral rings

- Wire rings

- External circlips

- Internal circlips

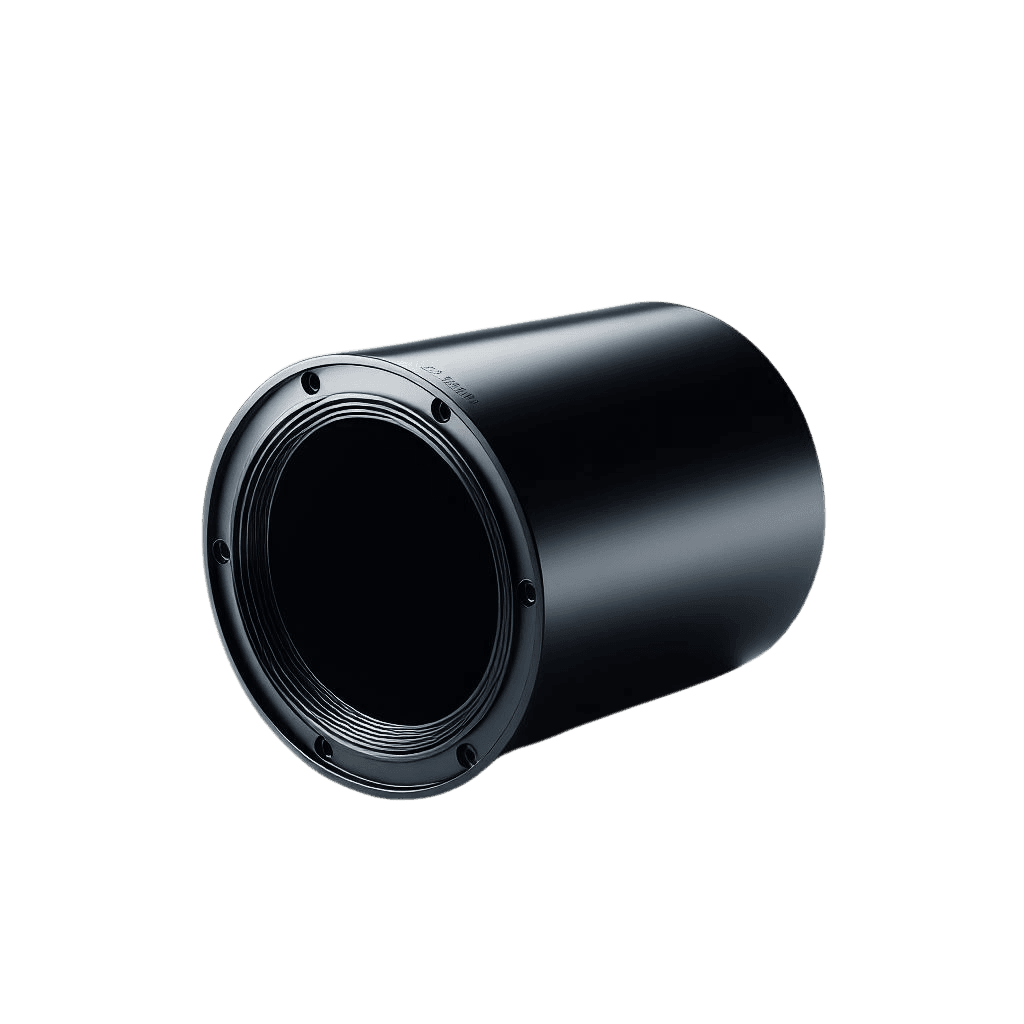

Linear bearings

Applications where MoS2 coating is benificial on Hydraulic cylinder.

- Robotic arms in manufacturing plants

- CNC routers in woodworking and metalworking industries

- Conveyor systems in distribution centers

- Automated packaging machinery in food and beverage production facilities

- Printing presses in commercial printing operations

- Material handling systems in warehouses and logistics centers

- Semiconductor manufacturing equipment in electronics fabrication plants

- Medical imaging devices in hospitals and clinics

- Aerospace industry equipment for assembly and testing

- Automotive manufacturing robots in car production plants

- Precision measuring equipment in quality control labs

- Textile machinery in textile manufacturing plants

- Metalworking machinery such as milling machines and lathes

- Food processing equipment in food manufacturing plants

- Pharmaceutical manufacturing machinery in pharmaceutical production facilities

- Packaging machinery in packaging plants

- Industrial automation systems for pick-and-place operations

- Laboratory automation equipment in research facilities

- Industrial 3D printers for additive manufacturing processes

- Hydraulic presses in manufacturing and fabrication industries

Mechanical joints & Fasteners

Applications where MoS2 coating is benificial on components of Fasteners and mechanical joints

- CNC milling machines

- CNC lathes

- Injection molding machines

- Press brakes

- Metal stamping presses

- Die casting machines

- Extrusion machines

- Forging presses

- Sheet metal cutting machines

- Grinding machines

- Gear cutting machines

- Wire forming machines

- Surface treatment equipment (e.g., plating lines)

- Heat treatment furnaces

- Welding robots

- Riveting machines

- Assembly line equipment

- Packaging machinery

- Material handling equipment (e.g., conveyors, cranes)

- Industrial robots for automation

Reciprocating pumps and compressor

Applications where MoS2 coating is benificial pumps and compressor

- Piston rings

- Piston skirts

- Piston pins (wrist pins)

- Cylinder bores

- Valve plates

- Valve springs

- Bearings (crankshaft bearings, connecting rod bearings, shaft bearings, thrust bearings)

- Crankshafts

- Connecting rods

- Cylinder heads

- Crossheads

- Seals (piston seals, shaft seals, gland packing)

- Wear bands

- Gaskets

- Valve seats

- Valve discs

- Cylinder liners

- Impellers

- Pump shafts

- Pump casings

- Pump diaphragms

- Pump liners

- Wear rings

- Valve balls

- Valve stems

- Valve cages

- Discharge and suction valves

- Pump housings

- Suction and discharge ports

- Flanges

- Bolts and fasteners

- Pump mounting hardware

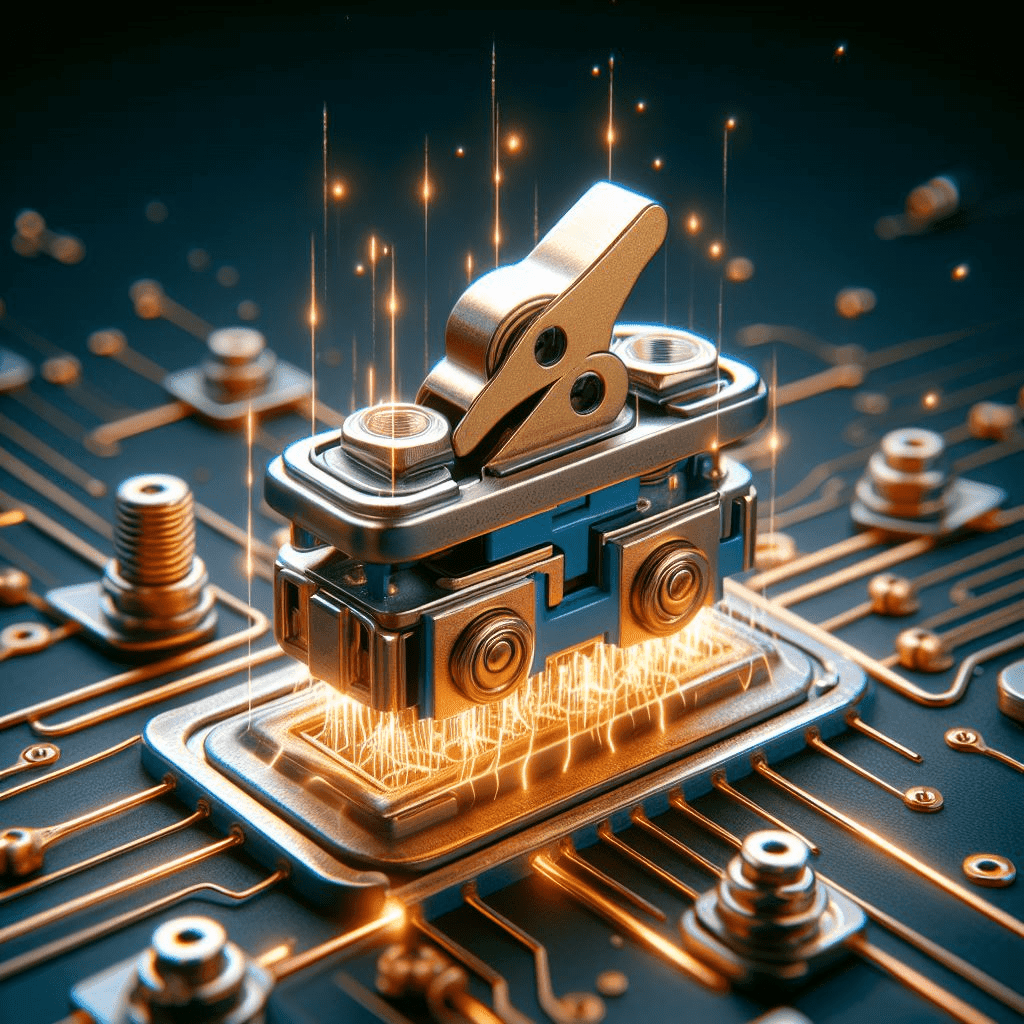

Electrical switch sliding contact

Applications where MoS2 coating is benificial on sliding switch in electronic board

- Electrical switches in consumer electronics (e.g., TVs, radios, remote controls)

- Automotive switches (e.g., light switches, window switches)

- Industrial control panels and machinery

- Household appliances (e.g., microwave ovens, washing machines)

- HVAC (heating, ventilation, and air conditioning) controls

- Lighting controls (e.g., dimmer switches)

- Power tools (e.g., drills, saws)

- Circuit breakers and electrical distribution panels

- Medical equipment controls (e.g., hospital beds, patient monitors)

- Aerospace and aviation controls (e.g., cockpit switches)

- Elevator and escalator controls

- Railway and subway control systems

- Marine navigation and control panels

- Agricultural machinery controls (e.g., tractors, combines)

- Security system controls (e.g., alarm panels, access control)

- Telecommunication equipment (e.g., phone systems, routers)

- Process control systems in manufacturing plants

- Audio equipment (e.g., amplifiers, mixing consoles)

- Laboratory equipment controls (e.g., analytical instruments)

- Gaming consoles and controllers

Key Features and Benefits of MoS2 Coatings

- Friction Reduction: MoS2 coatings drastically reduce friction between moving parts, leading to smoother operation and reduced wear and tear.

- Wear Resistance: The protective barrier created by MoS2 coatings enhances wear resistance, extending the lifespan of critical machinery components.

- High-Temperature Stability: MoS2 can withstand high temperatures, making it ideal for applications where traditional lubricants may break down.

- Corrosion Protection: MoS2 coatings also offer corrosion protection by preventing metal-to-metal contact and oxidation.

Advantages of MoS2 Dry Film Lubricant Coating

- Maintenance Reduction: MoS2 coatings minimize the need for frequent lubrication and maintenance, saving time and costs.

- Improved Efficiency: Reduced friction translates to improved energy efficiency and reduced operating temperatures.

- Environmental Friendliness: Dry film lubricant coatings eliminate the risk of oil leaks and contamination, making them environmentally friendly.

Embrace the Future with MoS2 Coatings

MoS2 dry film lubricant coating represents a cutting-edge solution for enhancing efficiency and reliability in industrial applications. By leveraging the benefits of MoS2 technology, businesses can optimize operations, reduce downtime, and extend the lifespan of critical machinery components.

What Our Client Says About Us

The MoS2 Coated Gears have found satisfactory working on ground station testing trials which was tested as dry film lubrication (Without grease, without oil)

ISRO

Scientist IsroThe ring traveler spinning after MoS2 Coating have definitely improved the yarn quality for us. It is definitely a good solution which is Made In India for Improving textile manufacturing machine efficiency

Lakshmi Ring Travellers

R&D Head“The Molybdenum Disulfide coating on bearing balls has qualified all our testing standards and quality clearances at VEM Technologies, Hyderabad, India.”

VEM Technologies

DFL Coating by HAES

MoS2-based dry film lubrication coating, designed to minimize friction and wear in machinery and equipment. This advanced coating provides a durable and long-lasting lubrication solution without the need for traditional liquid lubricants.

Key Features and Benefits

- MoS2 Technology: Molybdenum disulfide (MoS2) offers exceptional anti-friction properties, reducing wear and extending component lifespan.

- Dry Film Application: MolyKul Coat applies as a dry film, eliminating the mess and environmental concerns associated with liquid lubricants.

- Enhanced Performance: By reducing friction, MolyKul Coat enhances machinery performance and efficiency, optimizing operational output.

- Longevity and Durability: The durable nature of MoS2 ensures long-lasting lubrication, reducing the frequency of maintenance and downtime.