MolyKul MoS2 Grease for Industrial Applications

- Home

- MolyKul MoS2 Grease

MoS2 Solid Lubricant grease product: MolyKul Grease

- Trusted by Indian Airforce

- Versatile in industrial applications

- High Temperature Anti-Seize Grease

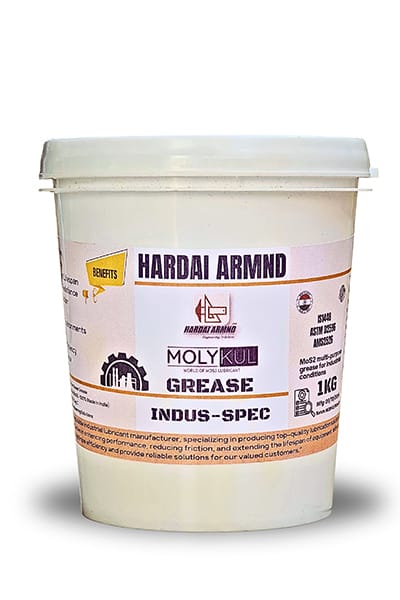

MolyKul Grease Indus-spec, a leading MoS2 anti-seize grease by Hardai ARMND, is engineered for aerospace and heavy-duty applications. Powered by molybdenum disulfide (MoS2), this high-temperature grease delivers MoS2 anti-seize grease benefits like low friction, corrosion resistance, and seizure prevention for bolts, bearings, gears, and pipe threads.

As a top MoS2 grease manufacturer in India, Hardai ARMND’s MolyKul Grease offers cost-effective MoS2 grease solutions that reduce maintenance costs with MoS2, prevent downtime with MoS2 grease, and enhance equipment longevity. Ideal for industrial MoS2 grease applications, it ensures maintenance efficiency, industrial reliability, and downtime savings in high-pressure and extreme environments. Choose Hardai ARMND for anti-seize grease for cost efficiency and industrial savings.

MolyKul Grease by HAES

MolyKul Indus-Spec 300

MolyKul Grease Indus-spec, with MoS2 anti-seize properties, delivers exceptional durability and long-lasting performance for high-temperature industrial applications up to 320°C. This reliable MoS2 lubricant ensures friction reduction and equipment longevity in demanding environments, minimizing maintenance costs and downtime for heavy-duty sectors.

MolyKul Indus-spec 600

MolyKul Grease Indus-spec, powered by MoS2 anti-seize technology, offers exceptional durability and long-lasting performance for high-temperature industrial applications up to 650°C. This reliable MoS2 lubricant ensures friction reduction and equipment longevity in extreme conditions, reducing maintenance costs and downtime for heavy-duty industries.

MolyKul Aero-Spec

MolyKul Grease Aero-spec, fortified with MoS2 anti-seize technology, offers exceptional durability and long-lasting performance for reliable lubrication in extreme environments of the aerospace industry. This MoS2 lubricant reduces friction, enhances equipment longevity, and minimizes maintenance costs and downtime for critical aerospace components like bolts, bearings, and gears.

| MoS2 grease | Parameters |

|---|---|

| Grease base Material | AP3 Lithium Moly Anti-seize grease |

| Mixing additive material | MoS2 (Molybdenum Di Sulphide) – Manufactured inhouse |

| MoS2 particle size (Min) | 10 nm (nano meter) |

| Service Temperature range | -60 degree celcius to 650 degree celcius |

| Colour | Black |

| Extreme Pressure | 15000 to 17000 PSI |

| Property | Anti-Seize, Anti-corrosive, Better thermal management, Longer Life |

| Applications | Automotive, Aerospace, Heavy Industry, Agriculture, Daily commutes, etc |

Applications of MolyKul Grease

MolyKul Grease Indus-spec, a versatile MoS2 anti-seize grease by Hardai ARMND, excels in industrial MoS2 grease applications due to its MoS2 solid lubrication and nanotechnology. This 100% Made-in-India high-temperature grease solves bearing jamming and motion jamming caused by conventional grease solidification under extreme environments, ensuring reliable lubrication and corrosion resistance.

Designed for anti-seize grease for cost efficiency, MolyKul Grease offers long-lasting equipment longevity and maintenance savings across industries like aerospace, mining, manufacturing, textile factories, defense, power plants, earth-moving machines, chemical factories, electric motors, transformers, agricultural equipment, and wire manufacturing. It prevents seizures, reduces friction, and minimizes maintenance costs and downtime for bolts, bearings, gears, and pipe threads in furnace applications and packaging factories.

MolyKul Grease for cost-effective MoS2 grease solutions, industrial reliability, and downtime savings in heavy-duty applications.

MolyKul Grease is Anti-Seize & Anti-Drying Longer life grease.

- Furnace Applications

- Mines and mining

- Manufacturing industry

- Packaing factories

- Textile Factories

- Defense & Aerospace

- Power plants

- Earth moving machines

- Chemical Factories

- Electric Motors

- Transformers

- Agricultural Equipments

- Wire Manufacturing

Features of MolyKul Oil

MolyKul Grease excels in extreme conditions, preventing galling, seizing, and corrosion with its tenacious adhesion. Its resistance to water, oxidation, and heat makes it ideal for harsh environments where conventional lubricants fail. The carefully formulated blend of base oils and additives provides exceptional lubrication, reduces friction, and minimizes wear. Its wide operating temperature range (Customizable) suits various applications like bearings, gears, and other moving parts.

In aerospace and industrial settings, high temperature industry grease’s anti-seize properties prevent seizing in high-load, high-speed applications, extending component life and reducing maintenance costs. Its consistent performance and reliability have earned it industry-wide trust like Indian AirForce. By choosing MolyKul Grease, industries can enhance equipment efficiency, durability, and safety, making it the ultimate anti-seize solution for demanding environments.

Features of MolyKul Grease

Key Benefits of MolyKul Grease Indus-Spec:

- Extended Bearing Life: Provides superior protection against wear and seizure, extending bearing life significantly.

- Reduced Maintenance Costs: Minimizes the need for frequent re-greasing, saving you time and money.

- Improved Efficiency: Reduces friction, leading to increased efficiency and energy savings.

- Enhanced Reliability: Ensures consistent performance in harsh environments and demanding applications.

Revolutionizing Maintenance: MolyKul Grease for Extended Equipment Lifespan

MolyKul Grease, an innovative anti-seize lubricant from Hardai ARMND Engineering Solutions, is revolutionizing maintenance practices in the industrial and aerospace sectors. Formulated with molybdenum disulfide, this exceptional grease extends equipment life, reduces downtime, and enhances operational efficiency.

MolyKul Grease’s unique composition provides superior lubrication and protection against wear and tear. Molybdenum disulfide, a highly effective solid lubricant, forms a protective layer on metal surfaces, minimizing friction and preventing metal-to-metal contact. This exceptional lubrication capability ensures smooth operation, reduces energy consumption, and extends the lifespan of bearings and other moving parts.

MolyKul Grease excels in preventing seizure and corrosion.

Ensuring reliable performance in extreme aerospace environments.

Its versatility extends to industrial applications, effectively lubricating bearings, gears, and moving parts under heavy loads and temperatures. By reducing wear and tear, MolyKul Grease extends equipment life, minimizes maintenance costs, and enhances safety, making it a game-changer in maintenance practices.

What Our Client Says About Us

Really it works as known as described about this product, I have bought and use in my different vehicles and result is amazing not for me but my mechanics also, they says you are real product finder…….

Raghav sibihar

As a PhD researcher, I procured the material from molykul.com as recommended. It demonstrated excellent performance under experimental conditions, maintaining stability across a temperature range of 300 to 450 degrees Celsius and withstanding high pressure loads up to 100 tons. The results were highly satisfactory and confirm its suitability for rigorous research applications.

Darshan Gowda, Bengaluru

“Molybdenum Disulfide Synthetic Grease Manufactured by Hardai ARMND Engineering Solutions has been accepted by Bareilly Air Force”

Indian Air Force

“Your Molybdenum Disulfide Grease, MolyKul Indus-Spec, has solved our long unsolved problem of fastener lubrication in transformers.”

Uttam (Bharat) Electricals Pvt. Ltd

Excillent product. Unlike other conventional greases, MolyKul grease do not get dried after continues uses and the texture of the grease, do not leave its marks on the surface. Still, lubricates with longer life. 5 star excillent product.

Mr. Shyam Parmar

MoS2 High Temperature Industrial Grease

Maximize machinery life and cut down on friction with Hardai ARMND as MoS2 grease manufacturers of innovative Nano grease. It’s packed with adaptable MoS2 for industry-specific tuning, boosting performance in cars, planes, and heavy equipment. Get more from your gear with our advanced lubricant.