High case study : MoS2 lubrication excellent success story

- Home

- High case study: MoS2 lubrication excellent success story in production

Trust the indian tech

we not only saves money

In manufacturing, we all aim for efficiency and reliability. One thing making a big difference lately? MoS2 lubrication. It cuts friction, extends machine life, and boosts productivity. Let’s see how it’s done that in real factories.

MoS2 lubrication success case study

- Case Study 1: Automotive Marvels

- Case Study 2: Aerospace Ascendancy

- Case Study 3: Industrial Ingenuity

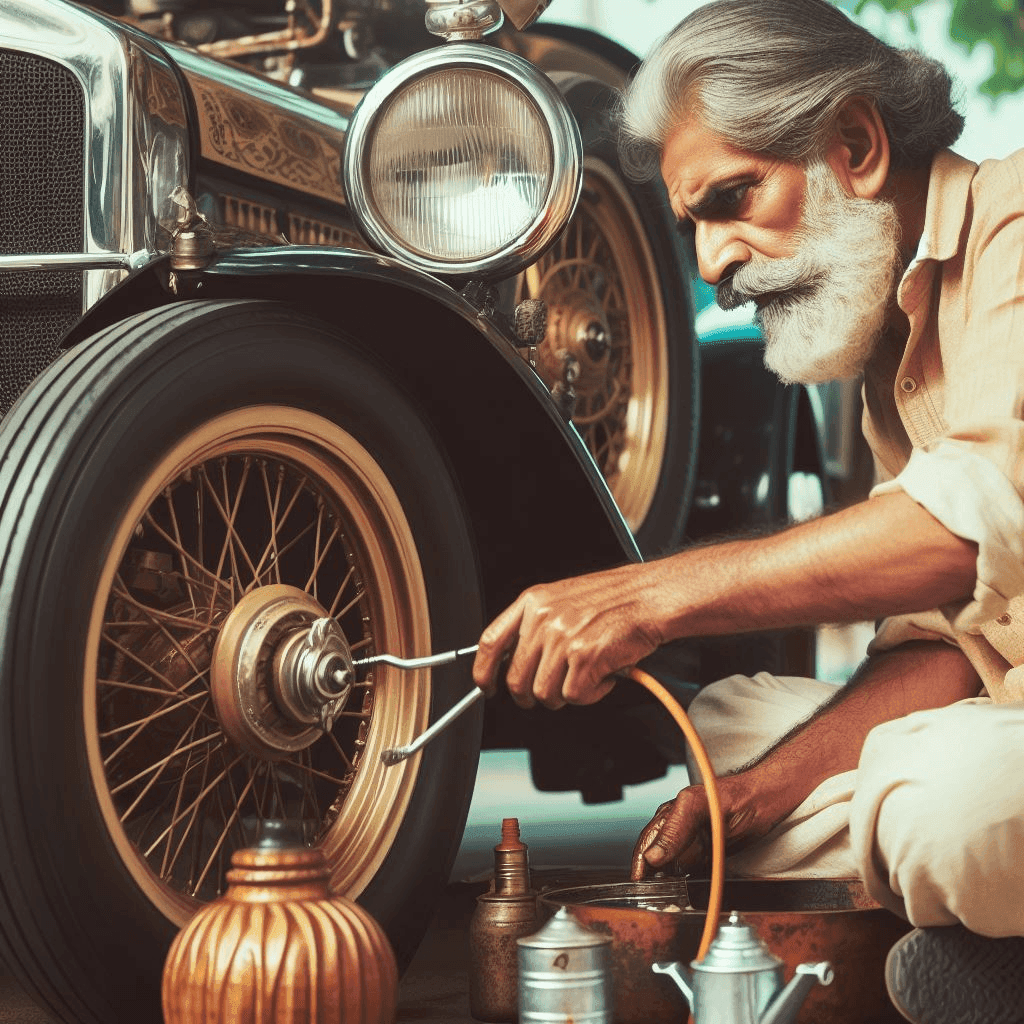

MoS2 lubrication as automotive wheels

In the bustling world of automotive engineering, even the smallest components can make a monumental difference. Take, for instance, the humble wheel bearing. It might seem insignificant, but it plays a crucial role in the smooth operation of a vehicle. Traditionally, these bearings have been lubricated with conventional grease. However, this approach has its limitations, especially when it comes to facing the harsh realities of the road.

Challenges with Conventional Grease:

Conventional grease, while effective to a certain extent, is prone to erosion and contamination when subjected to the rigors of varied environmental conditions. Whether it’s extreme temperatures, moisture exposure, or the relentless assault of dust and debris, conventional grease struggles to maintain its integrity over time. As a result, the wheel bearings it lubricates are vulnerable to premature wear and failure, leading to costly repairs and compromised safety on the road.

The MoS2 Solution:

Enter MoS2 coating—an innovative alternative that promises to revolutionize the way we approach wheel bearing lubrication. MoS2, or molybdenum disulfide, is a solid lubricant renowned for its exceptional durability and resilience in the face of adverse conditions. Unlike conventional grease, which can break down and lose effectiveness over time, MoS2 forms a robust, protective layer on the surface of the wheel bearing.

Overcoming Challenges with MoS2:

- Temperature Resistance: MoS2 excels in extreme temperature environments, remaining stable and effective even in the face of blistering heat or freezing cold. This ensures consistent lubrication performance regardless of the weather conditions.

- Moisture Protection: Thanks to its low-friction properties and high resistance to water washout, MoS2 provides reliable lubrication even in damp or rainy conditions. This helps prevent moisture intrusion and corrosion, prolonging the lifespan of the wheel bearing.

- Dust and Debris Mitigation: Dust and debris are no match for MoS2. Its slick, low-friction surface repels contaminants, reducing the risk of abrasive wear and tear on the wheel bearing components. This means smoother, quieter operation and extended maintenance intervals.

MoS2 lubrication on high speed bearing

In the realm of aerospace engineering, precision and reliability are paramount, especially when it comes to the intricate machinery powering turbomachines spinning at mind-boggling speeds, often exceeding 60,000 RPM. Traditionally, achieving optimal lubrication in such high-speed bearings has been a complex and costly endeavor, with traditional oil lubrication methods necessitating extensive research, resources, and meticulous design considerations. However, a groundbreaking solution has emerged, promising to revolutionize aerospace lubrication practices while drastically reducing costs: MoS2 coating.

The Cost Challenge:

The complexities associated with designing and implementing oil lubrication systems for high-speed bearings in aerospace applications are manifold. Research costs, resource allocation, design intricacies, manufacturing expenses, and the exhaustive assembly and testing processes all contribute to a significant financial burden. However, the introduction of MoS2 coating technology has flipped the script, offering a cost-effective alternative that doesn’t compromise on performance or reliability.

MoS2 Coating: A Game-Changer:

By applying a mere 1-micron thickness of MoS2 coating, with MoS2 particles measuring a minuscule 12 nanometers, aerospace engineers have unlocked a transformative solution. This ultra-thin yet incredibly durable coating boasts the remarkable ability to handle the extreme pressures, temperatures, and vibrations inherent to aerospace applications. Unlike traditional oil lubrication systems, which rely on intricate designs and costly maintenance regimes, MoS2 coating simplifies the lubrication process while delivering unparalleled performance and longevity.

The Cost-Saving Impact:

The adoption of MoS2 coating for high-speed bearings in aerospace turbomachines has yielded remarkable cost savings across the board. Research expenditures have been slashed, as the technology’s proven efficacy obviates the need for extensive exploration of alternative lubrication methods. Resource costs are minimized, as the streamlined application process requires fewer materials and man-hours. Design complexities are mitigated, as MoS2 coating offers a simple yet highly effective solution to lubrication challenges. Manufacturing expenses are reduced, thanks to the ease of integrating MoS2 coating into existing bearing systems. Moreover, assembly and testing costs are significantly diminished, as the robustness and reliability of MoS2-coated bearings negate the need for exhaustive validation procedures.

Conclusion:

In the dynamic and demanding world of aerospace engineering, innovation is key to overcoming challenges and driving progress. The adoption of MoS2 coating technology for high-speed bearings represents a paradigm shift, offering a cost-effective yet high-performance solution that meets the rigorous demands of aerospace applications. By revolutionizing lubrication practices and drastically reducing costs, MoS2 coating is propelling aerospace engineering to new heights of efficiency, reliability, and affordability. As turbomachines soar through the skies with newfound vigor and resilience, powered by MoS2-coated bearings, the future of aerospace ascendancy has never looked brighter.

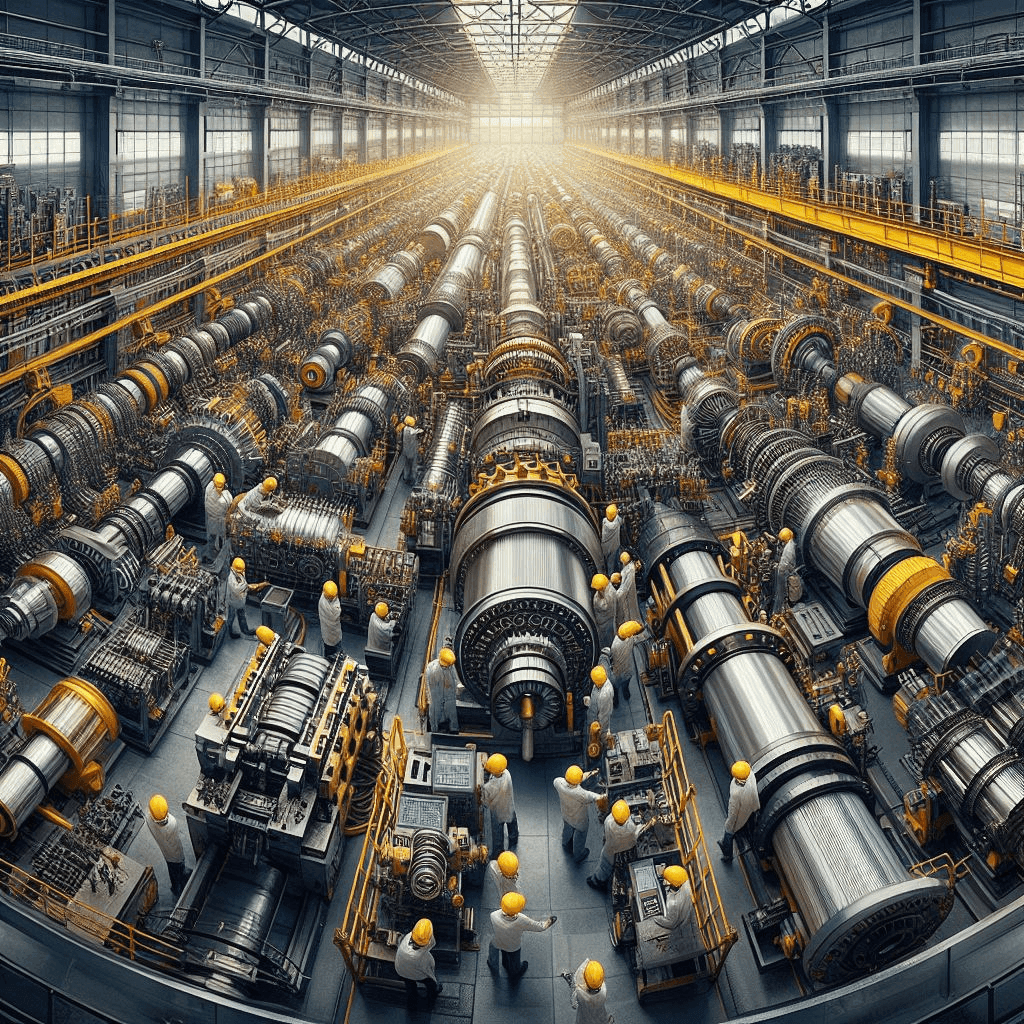

MoS2 lubrication for factory production cost

In the bustling environment of industrial manufacturing, machinery bears the brunt of heavy loads day in and day out. The constant stress on bearings and gears can lead to accelerated wear and tear, compromising efficiency and reliability. Moreover, the diverse chemical conditions, temperature fluctuations, and moisture levels prevalent in industrial settings pose a significant challenge to traditional lubrication methods. Enter MoS2 lubrication—a game-changing solution that is revolutionizing maintenance practices in factories worldwide.

The Challenge of Machinery Wear and Contaminated Lubricants:

In industrial facilities, machines operate under demanding conditions, subjecting bearings and gears to relentless mechanical loads. Over time, this constant stress can lead to premature wear and failure, necessitating frequent maintenance and lubrication. Compounding this challenge are the diverse chemical environments and fluctuating temperature and moisture levels present in many factories. These conditions can contaminate traditional lubricant oils, diminishing their effectiveness and requiring costly re-lubrication procedures.

The MoS2 Solution:

MoS2 lubrication offers a revolutionary approach to industrial machinery maintenance, addressing the dual challenges of wear and contamination with unparalleled efficiency. By incorporating MoS2 additives into lubricant oils, factories can enhance the lubricating properties of their machinery, significantly reducing friction and wear on bearings and gears. Additionally, MoS2’s exceptional resistance to chemical degradation and temperature extremes ensures that lubricants remain effective even in the harshest industrial environments.

Time and Cost Savings:

One of the most significant benefits of MoS2 lubrication is its ability to minimize downtime and maintenance intervals in industrial machinery. By providing superior lubrication and protection against wear, MoS2-coated components require less frequent re-lubrication, saving valuable time and resources. Moreover, the robustness of MoS2 additives means that machinery can operate at peak efficiency for longer periods between maintenance cycles, resulting in increased productivity and cost savings for factory operators.

Conclusion:

In the fast-paced world of industrial manufacturing, efficiency and reliability are paramount. By harnessing the power of MoS2 lubrication, factories can optimize machinery performance, minimize downtime, and reduce maintenance costs. With its ability to withstand extreme conditions and provide long-lasting lubrication, MoS2 is reshaping the landscape of industrial maintenance, offering a smarter, more sustainable solution for factories worldwide. As industries embrace the benefits of MoS2 lubrication, they pave the way for a future of enhanced productivity, reliability, and profitability in industrial manufacturing.

FAQ’s

Q1: What is MoS2 lubrication, and how does it differ from traditional lubrication methods?

A: MoS2 lubrication involves the incorporation of molybdenum disulfide (MoS2) particles into lubricants to reduce friction and wear on machinery components. Unlike traditional lubrication methods such as grease or oil, which rely on fluid-based lubricants, MoS2 creates a solid, low-friction coating on surfaces, offering enhanced durability and resilience in demanding operating conditions.

Q2: What are the key benefits of using MoS2 lubrication in automotive manufacturing?

A: MoS2 lubrication in automotive manufacturing provides several advantages, including reduced downtime, increased production output, and cost savings. By minimizing friction and wear on critical components such as wheel bearings, MoS2 lubrication helps optimize efficiency and reliability in automotive assembly lines.

Q3: How does MoS2 coating improve high-speed bearing lubrication in aerospace applications?

A: MoS2 coating offers a cost-effective alternative to traditional oil lubrication methods for high-speed bearings in aerospace turbomachines. By forming a durable, low-friction layer on bearing surfaces, MoS2 coating reduces wear and extends maintenance intervals. Additionally, its resilience to extreme temperatures, pressures, and vibrations makes it an ideal choice for aerospace environments.

Q4: In industrial settings, how does MoS2 lubrication address challenges related to machinery wear and lubricant contamination?

A: Industrial machinery faces constant mechanical loads that can accelerate wear on bearings and gears. Moreover, diverse chemical conditions and temperature fluctuations can contaminate lubricant oils, reducing their effectiveness. MoS2 lubrication mitigates these challenges by providing superior lubrication and resistance to contamination, resulting in reduced maintenance requirements and increased machinery uptime.

Q5: What time and cost savings can be expected from implementing MoS2 lubrication in industrial facilities?

A: Implementing MoS2 lubrication in industrial facilities can lead to significant time and cost savings. By minimizing downtime and maintenance intervals, MoS2-coated components reduce the need for frequent re-lubrication and repairs. Additionally, the enhanced durability of MoS2-coated machinery results in increased productivity and reduced operating costs over the long term.

Q6: How can I integrate MoS2 lubrication into my manufacturing operation?

A: Integrating MoS2 lubrication into your manufacturing operation involves selecting suitable lubricants containing MoS2 additives and applying them to machinery components as per manufacturer recommendations. Consultation with lubrication experts and conducting thorough testing can help ensure successful implementation and maximize the benefits of MoS2 lubrication in your specific industrial setting.

Leave A Comment